GAS HYDRATE PRODUCTION TEST: FROM EXPERIMENTAL SIMULATION TO FIELD PRACTICE

-

摘要: 天然气水合物研究的终极目标是对其进行有效的开发利用,即实现长期安全、高效地开采,而水合物试采只是迈出了第一步。数十年的室内水合物开采方法实验及其数值模拟研究取得了显著的成果,为天然气水合物试采奠定了坚实的基础。加拿大、美国等国家先后在陆地冻土区进行了水合物试采工作,试验成果为海域水合物试采提供了宝贵的经验。2013年和2017年,日本、中国先后在不同海域实施了天然气水合物试采,并取得了成功,这是天然气水合物研究的一个里程碑式的进步,标志着天然气水合物开采技术研究从室内实验模拟逐步转到产地实施。本文回顾了各种水合物开采方法的原理及其模拟实验成果,简要介绍了水合物开采数值模拟方法与进展,评述了水合物试采的前期关键技术准备及场地实施效果,讨论了每种技术方法的局限性及面临的挑战,并针对海洋天然气水合物开采面临的科学与技术问题提出了建议。Abstract: The eventual aim of gas hydrate research is to develop and utilize the hydrate resource effectively, that is to achieve long-term exploitation safely and efficiently. Gas hydrate production test is just the first step towards this destination. In the last several decades, great achievements for gas hydrate exploitation method studies have been made by laboratory experiments and numerical simulations, which have laid a solid foundation for gas hydrate production test. In the permafrost areas, the gas hydrate production tests were carried out by the US, Japan and Canada in the Mallik program at the Mackenzie Delta, and the U.S. in the North Slope of Alaska, respectively. The results provide some valuable experiences for gas production from marine gas hydrate. In 2013 and 2015, Japan and China carried out successfully the marine gas hydrate production tests in different sea areas respectively, suggesting landmark achievements in gas hydrate researches. It indicates that the study of gas hydrate exploitation technology has changed gradually from laboratory simulation to field practice. In this paper, we reviewed the principles and the experimental results for various gas hydrate exploitation methods, introduced briefly the numerical simulation methods and their progresses, discussed the key technology preparation required for gas hydrate production tests and the field practice effect. We also discussed the limitation and challenges faced by each method. Some advices were presented on the science and technology issues of gas production of marine gas hydrate resources.

-

天然气水合物广泛分布于高纬度陆地永久冻土带与大陆边缘海沉积物中,是一种重要的潜在能源,如何安全高效地对其进行开采利用已经成为当前国际上的研究热点。在低温和高压条件下,天然气(通常为甲烷)分子与水分子生成笼型水合物,气体分子包裹于由水分子形成的笼中,形成稳定的晶体结构。气体分子要从晶体的笼中逸出,则必须克服气体分子与水分子之间的范德华力[1],这就决定着天然气水合物开采方法与常规油气不同。

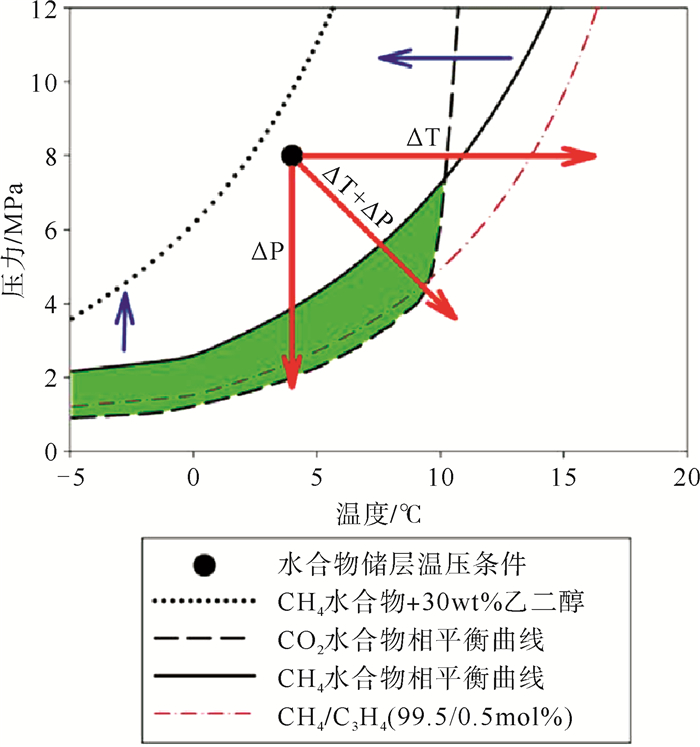

天然气水合物开采的思路是将其原位分解成天然气和水,即原位打破储层中水合物稳定存在的P-T条件。因此,水合物开采除了创建气流管道外,还涉及原位分解水合物的技术。目前提出的开采方法主要有降压法、热激发法、注化学抑制剂法和CO2置换法。其中,降压法、热激发法通过改变甲烷水合物P-T条件使其不稳定而分解,化学抑制剂注入法可改变水合物体系相平衡边界,使水合物失稳而分解。如图 1所示,为了开采在水合物储层的任一点(4 ℃, 8 MPa)的甲烷水合物,就必须升温或降压使其失稳分解,温度最小需要升高7 K或者压力至少需要降低4.2 MPa才能实现开采的目的;如果采用注入化学抑制剂法,如注入乙二醇,则需要的浓度约为30 wt%。

![]() 图 1 天然气水合物开采方法示意图[2](ΔP:降压法;ΔT:热激发法;ΔP+ ΔT:降压法+热激法;向左、上蓝色箭头:化学抑制剂注入法;绿色阴影部分:CO2置换法)Figure 1. Schematic digram of commonly proposed gas recovery methods

图 1 天然气水合物开采方法示意图[2](ΔP:降压法;ΔT:热激发法;ΔP+ ΔT:降压法+热激法;向左、上蓝色箭头:化学抑制剂注入法;绿色阴影部分:CO2置换法)Figure 1. Schematic digram of commonly proposed gas recovery methods由于天然气水合物开采存在耗资巨大、技术不成熟、环境风险高等问题,还需要进行深入研究与长期的技术准备。目前,水合物开采技术研究仍以室内为主。经过数十年的室内模拟实验、数值模拟研究,获得了大量的实验数据,为场地天然气水合物试采提供了宝贵参数,为天然气水合物试采奠定了基础。

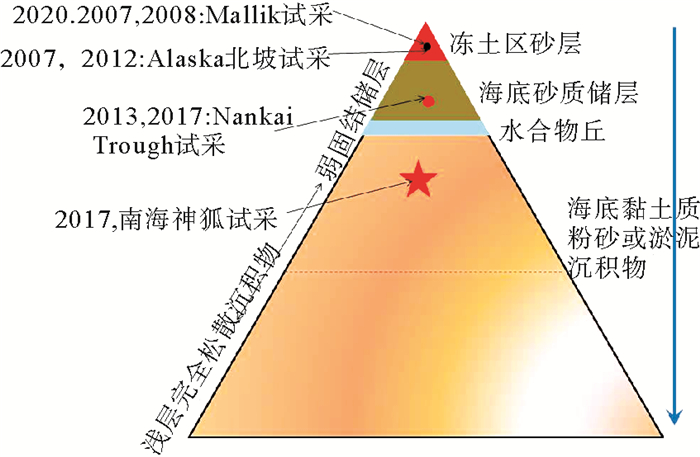

自2002年起,国际上已先后进行了7次天然气水合物试采,其中陆地冻土区4次,海域3次,主要位于以下地区:(1)加拿大麦肯齐三角洲冻土区, 日本、加拿大、美国、印度、德国合作于2002年、2007年分别通过注热法和降压法进行试采, 2008年采用简单降压法进行试采;(2)美国阿拉斯加北坡冻土区,美国和日本合作2012年通过CO2置换和降压法联合方式进行试采;(3)日本南海海槽,2013年采用排水降压法进行首次试采,2017年进行了第二次试采;(4)南海北部神狐海域,中国在2017年5—7月成功实施天然气水合物试采,采用降压法60天产气30.9万m3,创造了连续稳定产气最长时间记录。这些试采工作积累了大量的数据资料,在天然气水合物开发产业化道路上迈出了坚实的一步。

本文拟通过对天然气水合物开采方法进行较全面的评述,从室内模拟实验及场地试采两个方面论述水合物开采技术的进展及其取得成果,探讨各项技术缺陷与面临挑战,并对天然气水合物开采方法与关键技术提出了建议,可望对天然气水合物高效安全开采有所借鉴。

1. 天然气水合物开采方法及模拟实验

1.1 模拟实验装置

模拟实验装置是开展室内水合物开采方法研究的基础条件,通过研发不同种类的实验装置可开展不同需求的开采实验研究。模拟实验装置一般由高压反应系统、低温控制系统、实验测试系统和数据采集系统组成。高压反应系统由高压反应容器、气液供给模块和增压模块等组成;低温控制系统由恒温浴槽或恒温室、温度控制模块组成;实验测试系统一般由压力、温度、产气速率、物性参数测量模块组成,用来监测水合物分解过程中各物理量的变化。

模拟实验装置经历了从几百毫升体积到几百升、由一维到三维的发展阶段,其测试技术也由最初单一参数向多参数联合监测发展,能满足开展不同水合物开采方法的实验研究。国内外具有代表性的水合物模拟实验装置主要有:美国科罗拉多矿业大学[3]、美国地质调查局[4]、美国橡树岭国家实验室[5]、美国西弗吉尼亚大学[6]、美国国家能源技术实验室[7]、加拿大英属哥伦比亚大学[8]、青岛海洋地质研究所[9]、中国石油大学(华东)[10, 11]、大连理工大学[12]和中国科学院力学研究所[13]等。

近年来,一批较大尺度的水合物开采模拟实验系统陆续问世,主要包括中国科学院广州能源所[14]、中国石油大学(北京)[15],日本产业技术综合研究所[16]及德国波茨坦亥姆霍兹中心[17],这些大尺寸的实验装置有效地消除了由于反应釜体积太小引起的边界效应,使实验条件更接近海底环境。2016年,青岛海洋地质研究所研发一套国内尺寸最大(520升)、钻采一体化的水合物开采技术及过程监测综合实验系统,可模拟含水合物地层环境,监测水合物的含量、分布;可模拟钻井过程,并通过降压法开采水合物,实时测量管流中产气及产水速率、产砂粒径及产砂量、温度和压力等多物理参数,为水合物中长期开采技术难题的解决提供实验平台。

1.2 降压法

降压法原理是通过降低水合物储层孔隙压力使其低于该区域温度对应的水合物相平衡压力,打破水合物稳定条件而使其分解[18]。降压手段通常是降低水合物层下伏游离气层的压力或抽取水合物储层流体。降压法开采水合物过程无热量消耗和损失,不需要连续激发,成本较低,是所有开采方法中的首选方法,可实现大面积的开采,特别适用于存在下伏游离气层的水合物藏的开采。

与其他方法相比,降压法得到了更全面、更深入的研究,从最初仅对温、压参数变化及产水产气规律进行描述,发展到综合考虑地层、降压条件等因素的产气规律及理论分析[19]。实验表明,水合物降压分解过程一般可分为快速分解、缓慢分解和分解结束3个阶段,若水合物在沉积物中分布均匀时,会出现明显的分解前缘[20]。水合物分解为吸热过程,随着水合物分解引起局部温度降低,会导致后期水合物分解缓慢或停滞。因此,降压法要维持持续高效产气,需要有一定的热力梯度沉积层或额外提供热量[6, 9]。影响降压开采效率的因素主要包括降压幅度、环境温度、水合物初始饱和度及沉积层特性等,其中,降压幅度对水合物分解过程起主导作用,降压幅度越大,水合物分解越快[21];环境温度对分解速率的影响主要体现在水合物储层压力降至设置的分解压力后,环境温度越高,水合物分解越快;水合物饱和度对分解速率有较大影响,在特定饱和度条件下水合物分解最快[22]。为了探讨沉积层特性对水合物分解产气规律的影响,Ahn等[23]在实验中采用泥砂混合层的沉积物来进行模拟实验,通过在反应釜两端各装入25 cm厚的泥层而中间夹着一个50 cm的砂层来模拟泥砂混合沉层,在甲烷水合物饱和度为50%时进行降压分解,结果表明,在分解过程中产水比产气更早,气体扩散加速了水的流动。泥层对水合物稳定性及水、气产出的影响,还需要进一步的研究。

1.3 热激发法

热激发法的原理是通过提高水合物储层温度使其高于该区域孔隙压力对应的水合物相平衡温度,打破水合物稳定存在条件使其分解[24, 25]。热激发法主要手段包括:向水合物层泵入热水、蒸汽等热流体,或利用井下加热技术如电磁、微波直接加热。注入热水时,热水从地面或海底向水合物储层输送过程中会有大量的热损失,经济可行性差。直接加热时,引入加热源直接对水合物储层加热,避免了传输管道的热损失,且此方法适用于不同地质条件下的不同类型水合物资源[26]。热激发法的优点是人为主动干扰水合物储层的温度,能有效地控制水合物开采速度,但会造成大量的热损失,热效率很低,注热能力及技术也会限制该方法的使用。

注热水法实验表明[27],在水合物饱和度相同条件下,注水温度越高、流速越大,水合物分解越快,其中注水速度对水合物分解速率起主导作用,能量分析表明注水速度越大能量效率和热效率越高。在渗透率相对较大的多孔介质中,对不同饱和度(16%,32%,48%,64%)的水合物层进行注热盐水实验,发现水合物饱和度低于48%时,水合物分解速率较快,气体能够及时逸出[28]。采用单点电加热法的实验表明,水合物储层升温速度缓慢,水合物分解时间长,能量利用率较低,成本较高[29]。

1.4 化学抑制剂注入法

注入化学抑制剂法原理是基于注入某些化学试剂,如甲醇、乙醇、乙二醇、丙三醇、盐水、氯化钙等试剂,可降低水合物的稳定条件,从而造成部分水合物分解[30],水合物的分解率是抑制剂注入率的函数[31]。注入化学抑制剂法能有效地改变水合物相平衡条件,人为控制分解水合物的速度,但该法的主要缺陷是化学试剂昂贵,开采速度缓慢,还会带来环境污染问题,不宜用于海洋天然气水合物的开采。

化学抑制剂可分为热力学抑制剂和动力抑制剂,热力学抑制剂比较常用,如甲醇、乙醇等。相比甲醇试剂,乙醇毒性低,且密度比甲醇大更容易使水合物分解[32]。注入乙醇溶液实验表明,水合物分解速率取决于温度、压力、注入速度、乙醇浓度及接触面积等参数,产气速率还决定于水合物层的渗透率[33]。NaCl也具有抑制特性,在含水合物的Berea砂岩中,注入一定浓度NaCl溶液,当溶液浓度为3.45 wt%时,水合物分解且产气速率较快,当溶液浓度增加至20 wt%时,因在沉积物孔隙中形成不渗透的NaCl层,使沉积层渗透率降低,导致水合物分解速率缓慢[34]。由于化学抑制剂成本高且污染地层,一种新型的抑制剂-动力学抑制剂出现了,该抑制剂改变水合物分解的动力学性质,使用很小剂量(最多1 wt%)可明显加快水合物的分解速率,同时减少了对海洋环境的危害[35]。

1.5 CO2置换法

CO2置换法原理是利用CO2水合物在相同条件下比甲烷水合物更稳定,即在相同的温度条件下,CO2水合物保持稳定需要的压力更低。这样在较低的压力下CO2水合物较易形成并保持稳定,而甲烷水合物则会分解[36, 37]。通过向甲烷水合物储层通入不同形态CO2或CO2/N2混合气,随着CO2水合物生成,释放的热量同时引起甲烷水合物分解,这种方法既可在确保地层稳定条件下获得甲烷,又能埋存CO2以减轻温室效应,是一种具有经济和环境双重效益的开采方法,但该法置换效率低,难以满足商业化开采需求。

目前,CO2置换法的研究范围涉及了微观尺度、孔隙尺度到宏观尺度。微观尺度研究主要采用激光拉曼光谱、X-射线衍射、中子衍射等技术,CO2置换反应从微观角度看就是甲烷分子从水合物晶体中逸出同时CO2分子进入水合物晶体结构中,反应的驱动力为甲烷水合物相与注入CO2相之间的化学势梯度[38]。如果客体分子除了CH4之外还含有大分子C2H6、C3H8等混合气水合物,CO2置换过程还伴随着水合物结构变化[38, 39]。孔隙尺度研究主要利用核磁成像技术对CO2置换动力学进行研究,通过MRI信号强度分析,发现在含甲烷水合物的多孔介质中注入液态CO2时有CH4气逸出。宏观实验研究表明,CO2置换效率取决于样品体积、水合物饱和度、沉积物的渗透性、水合物赋存形式以及注入CO2的压力和温度等实验条件[40-42]。通常情况下,置换反应经历快速反应和缓慢反应两个阶段,前者受表层甲烷水合物分解速率控制,而后者受气体的扩散速度控制[43]。需要说明的是,CO2置换法产出的气体为混合气而不是纯甲烷气,对混合气提纯还需要较高的成本。

1.6 其他方法

除了上述4种水合物开采方法外,科研人员又提出了一些其他新技术新方法,主要包括:(1)固体开采法:将海底固态的天然气水合物直接采集并拖至浅水区使其进行控制性分解,回收分解气体,该方法进一步演化成矿泥浆开采法或混合开采法[44];(2)机械-热采法:结合水合物地层的地质力学性质而提出的一个全新的水合物开采概念模型,该方法以对流传热的方式充分利用海水的热量来分解较小体积的水合物,同时利用开采气体膨胀作功转化为开采所需机械能,该法理论上可以达到很高的开采效率,适合于具有水合物分布集中、储量大而常规开采方法效率较低的水合物地层。但该方法涉及多个复杂的工程问题难以解决,而且其转化机理均尚不明确[45]。此外,针对海底表层和浅层水合物,Dong等[46]提出了将水合物从海底沉积物分离的模块化系统,包括4个模块:海底采矿机器人,水合物沉积物采集和处理中心,岸基平台,沉积物回填机器人。

1.7 讨论

目前,降压法、热激法、CO2置换法及注入抑制剂法已在实验室内进行了大量模拟实验,其中前三种方法已应用于不同地区的天然气水合物试采中。

降压法是公认的最为经济有效和简单方便的开采方式,已经应用于2007、2008年加拿大Mallik水合物试开采[47-50]、2012年美国阿拉斯加北坡水合物试开采和2013年日本南海海槽地区水合物试开采[50],短期开采效率较高,但由于不同地区的水合物储层特性不同,降压速率及降压幅度不好掌握,很容易造成地层破坏性大量出砂或储层的整体失稳,上述3次水合物试采工作都是由于地层大量出砂造成井口堵塞而被迫停止。因此,降压法要实现商业开采仍然存在一些技术难题需要解决。热激法已经应用于2002年加拿大Mallik地区水合物试开采[51],结果表明其热损失太大,短期开采效率明显低于降压法,经济性差,单独使用远远不能满足商业开采的需求。CO2置换法已经尝试应用于2012年美国阿拉斯加北坡水合物试开采,采用了CO2置换与降压联合法 [52],结果发现因水合物地层中的置换反应十分缓慢,该次试采产气量大部分贡献来自于降压法,CO2置换对于产量的贡献非常有限[53]。因此,单独将CO2置换法应用于水合物商业开采可能性不大。注入化学抑制剂法会对环境造成污染,成本昂贵且开采效率低,已经基本排除了应用于商业开采的可能性。此外,固体法通过挖掘富集水合物地层,粉碎后获得含水合物沉积物颗粒,以一定物理手段分离出固态水合物,进而供热或降压使其分解为液态水和气态甲烷。固体法仍处于概念模型阶段,技术难度高,不可预知费用大,应用于商业开采存在较大困难。

上述各种开采方法单独使用都存在一定的局限性,因此,采用降压-加热联合法一定程度上弥补降压法的缺陷。通过与单一使用降压法或注热水法实验结果对比,联合法在能量效率、产气平均速率及产气量上具有明显优势[54]。另一项实验研究表明,在水合物饱和度为40%石英砂中,实验压力为6 MPa时,在90分钟内,联合法产气量是降压法的3.6倍[55]。总之,各种开采方法有其各自的优点,也都各有其局限性,至今尚未有安全、持续高效地开采天然气水合物的可靠方法,还需要进行深入研究和持续的技术积累。

2. 水合物开采数值模拟

2.1 数值模拟器

目前用于天然气水合物研究的数值模拟软件主要有:TOUGH+HYDRATE (美国)、MH-21 HYDRES (日本)、STOMP-HYD (美国)和CMG-STARS (美国),其中,前两个软件应用最广。

MH-21HYDRES是为日本水合物研究项目MH21研发的模拟器,该模拟器考虑了4种组分(甲烷、水、甲醇和盐分)、5种相态(气相、液相、冰相、水合物相、盐)的情况,包含了水合物相平衡模型和动力学模型,考虑了水合物和冰的生成放热和分解吸热,添加了渗透率模型,可以模拟降压、热激发、注入化学试剂法及各方法联合开采甲烷水合物的过程,该模拟器已应用于日本南海海槽水合物藏开采模拟与分析[56]。

TOUGH+HYDRAT是由美国劳伦斯伯克利国家实验室研发的水合物模拟软件,经多年不断改进和完善,在水合物模拟方面具有较强优势,应用广泛。经过Moridis[56, 57]多次对模型改进和优化,2008年发展成现今应用广泛的TOUGH+HYDRAT通用模拟器,其包含了水合物形成分解的平衡模型和动力学模型,充分考虑了4相(水合物、冰、液、气)、9组分(水合物中分离出来的甲烷、天然甲烷、水合物分解的第二种碳氢组分、第二种天然碳氢组分、水、水合物、水溶性抑制剂和盐),可模拟与分析降压、热激发、注入化学抑制剂等条件下水合物分解的过程和机理,用于对含水合物的地质环境系统模拟[57]。

2.2 不同条件下水合物开采数值模拟

在进行天然气水合物试采前,除了要做大量的室内模拟实验外,还要开展数值模拟研究,针对不同的水合物储层,模拟产气产水过程。Moridis等 [58]利用EOSHYDR2模型对加拿大Mallik地区5种不同水合物储层类型的产气情况进行模拟分析,结果表明,当水合物稳定带下存在游离气层时,利用降压法开采效果较好,且水平井比垂直井更具优势。

Myshakin等 [59]根据钻井数据获取储层的地质构造信息,利用阿拉斯加北坡78口钻井的录井信息,建立了地质统计学孔隙度模型,可提供孔隙度、水合物饱和度和渗透性的三维异相性特征。建立了三维数值模型对水合物赋存区进行降压开采模拟,结果表明,在恒定的井底压力下,倾斜井开采效果比垂直井更好。

Kurihara等 [56]利用MH-21 HYDRES模拟器对日本南海海槽东部水合物储层开采情况进行模拟。根据勘探获得的水合物分布特征,选取了不同储层特征的三口井分别进行模拟计算,得到以下结论:降压法是最有前景的水合物开采方法,因储层具有相对较高的渗透率,当井底压力为3 MPa时,可获得储层30%~60%的甲烷气;水合物降压分解过程中,井底压力的增加及热量供给的减少会减缓水合物的分解;当产气速率很高时,井附近可能会因温度降低导致水合物的二次生成,井筒加热可有效防止该现象的产生;在储层渗透率较高时,热激发法可提高产气效率,因此提出降压后再进行注入热水的二次开采方式是可行的;利用模型对降压、井口加热及注热水法进行经济效益分析,降压法具有经济可行性。

针对南海神狐海域天然气水合物储层,研究人员利用TOUGH+HYDRATE软件对其开采潜力进行了数值模拟研究[60-64]。结果表明,单独采用热激发法开采时,井孔高温热源的辐射半径很小,水合物受热分解速率缓慢;在注热和降压联合开采中,注热对水合物分解的贡献很小,水合物分解主要由降压引起。Sun等[65]根据南海神狐海域SH7井数据,建立了二维数值模型,并对该水合物储层进行降压法开采数值模拟,结果表明,具有较高渗透率的上层沉积物中水合物先分解,在水合物分解后期,主要是底部低渗透率沉积层中水合物分解,而在中间水合物沉积层中观察到有水合物二次生成现象,会影响底层水合物分解。

3. 水合物试采关键技术

3.1 井位优选技术

海洋天然气水合物试采井位优选应该包括试采地点的选择和试采详细坐标站位的优选两个层次。

试采地点的选取,要求水合物试采矿体具有综合调查程度高、矿体规模大、矿体水合物丰度高、地理位置便于补给等特征,同时要满足一定的科学实验目标条件。2017年,我国首次海域天然气水合物试采选址南海北部神狐海域,主要原因是:该区域水合物有利成矿区块多、面积大;水合物储层的空间分布较为熟悉;神狐海域距珠海九洲直升机场及深圳物资补给码头均约300 km,便于人员更换及生产物资的补给[66]。日本2017年的第二次天然气水合物试采选择与2013年同一地点,除了该区天然气水合物综合调查程度高、矿体总体规模成熟、丰度较高、地理位置便于补给等原因外,更重要是验证第一次试采过程中面临的关键技术问题(如防砂技术可靠性、出砂规律、井下气水分离效率及长期稳产的可能性等)。

试采站位坐标的确定需要综合考虑试采井控制区内部水合物储层的厚度、埋深、微裂隙发育程度、水合物饱和度、纵向及平面非均质性、渗透率、储层上覆层工程地质特性、海底地貌等[67]。可以借鉴目前常规油气井开发过程中的井位优选方法,综合考虑上述工程、地质因素,从定性和定量两个角度出发,建立一定的数学模型(如综合模糊评判等),在一定框体范围内优选最佳试采站位。2013年,日本首次海域天然气水合物试采就是通过对“β ”水合物富集带进行精细3D地震反射模式分析(含河道相解释、高密度速度分析、P波阻抗反演分析等),最终选择AT1-MC作为首次海域天然气水合物试采站位[68]。

野外试验性开采和数值模拟、实验模拟研究表明,赋存于中-粗砂质沉积物中的天然气水合物有利于开采,因此海洋环境的中-粗砂质天然气水合物储层被认为是最经济可行的开采目标,是当前国际上海洋天然气水合物勘探和开发的优先目标。尽管如此,目前国内外针对海洋天然气水合物试采尚未形成体系化的井位优选方法。预计在今后较长一段时间内,综合水合物储层的工程、地质特性开展水合物开采井站位优选研究,是推进海域天然气水合物产业化进程的重要研究方向之一。

3.2 试采井降压技术

尽管降压法已经被国内外历次天然气水合物试采证明是最具应用前景的开采方法,但在实际海洋天然气水合物试采过程中,采用不同的降压技术,对解决储层失稳、产能较低等一系列的工程问题至关重要,甚至决定着试采的成败。根据不同的降压操作程序,海域天然气水合物试采过程中的降压控制过程大致可以分为一次性快速降压、连续缓慢降压、多梯度逐渐降压[69]、脉冲波动间歇性降压等模式,不同降压控制技术控制的关键参数包括降压幅度和降压速率。

加拿大Mallik2L-38井采用交错降压模式,逐步将井底压力降低至4.5MPa。2013年日本南海海槽ATC-P井采用一次迅速降压模式生产,开泵后将井底流压直接从13.5 MPa降低至约4.5MPa,虽然生产初期取得了比较理想的产能,但是在第6天的时候,储层发生整体坍塌,破坏性大量出砂迅速发生井筒砂埋,试采被迫终止[70]。此后,Uchida等[71]通过数值模拟证明:在一定降压幅度条件下,降压速率对产气量的变化影响不大,但是较大的降压速率一定会加剧地层的出砂,并引起其他工程问题。无论从工程实践角度还是室内研究角度,合理的降压幅度控制都是海域天然气水合物试采成功的关键。尤其是对于粉砂质储层而言,在生产初期采用逐步阶梯式降压,有利于储层保护,从而延长试采周期。

因此,要建立准确的天然气水合物试采井降压制度,首先需要根据地质条件进行产水量、产砂量和产气量数值模拟,然后基于模拟结果,综合考虑地层出砂临界压降条件、地层失稳破坏临界压降条件、井筒携砂临界水/气流速条件、平台井口砂液处理能力等情况,进行降压工作制度的制定。

3.3 出砂管理技术

出砂管理技术的关键是不同生产模式下地层出砂情况的预测、防砂方式的优选、防砂筛管的研发及施工工艺参数(含完井液)的选取[72]。在天然气水合物试采发展历程中,不同生产模式下地层出砂情况预测相关的技术发展相对滞后于水合物试采本身的发展历程,目前可见的关于天然气水合物储层出砂情况预测研究的主要途径是:(1)建立多场耦合出砂模型,通过有限差分求解,形成出砂模拟器[73, 74];(2)基于Flec3D和PFC等大型商业软件,建立商业软件之间的接口,通过数值模拟进行求解[75]。由于天然气水合物试采经历有限,对不同完井方式的效果验证不充足,目前暂时没有形成任何一种可以被认为是极具推广价值的天然气水合物开采井防砂方式,历次天然气水合物试采过程中所采用的防砂方式汇总如表 1所示。

表 1 天然气水合物试采和出砂与防砂情况Table 1. Overview of sand production and sand mamagement status during hydrate exploitation试采井位 防砂方式 效果 加拿大Mallik 5L-38(2002) 防砂机械筛管防砂 有砂产出 加拿大Mallik 2L-38(2007) 射孔完井,未防砂 出砂造成ESP损坏 加拿大Mallik 2L-38(2008) 机械筛管防砂;泵入口加防砂网 有砂产出 美国阿拉斯加(2012) 机械筛管防砂 有砂产出 日本AT1-P(2013) 裸眼砾石充填防砂 出砂造成ESP损坏,试采终止 日本2017-001* 先期膨胀GeoForm筛管 防砂失败,井筒砂埋 日本2017-002* 井下膨胀GeoForm筛管 效果较好 *日本2017年海域天然气水合物试采两口井的具体站位数据目前暂未见报道,因此, 采用2017-001、2017-002代替。 其中,日本AT1-P(2013)天然气水合物试采井采用裸眼砾石充填方式完井,其防砂筛网的内径尺寸为4.894”(124.3 mm)。该井地层砂中粒径分布小于156 μm的累重为90%,细分砂与黏土粒径分布于437~449 μm之间的累重为90%。砾石尺寸使用40~60目,筛管孔径115 μm,类型为Excluder 2000精密筛管。施工使用选择CS-300TM砾石充填体系,砾石充填过程中共计2 132 kg(约2.12 m3)砾石被充填进入环空,这大约是计算体积0.88 m3的3倍。裸眼砾石充填防砂工艺失败的原因是:随着水合物的不断分解,地层亏空量逐渐变大,因此会导致砾石充填层发生蠕动,出现砾石层上部的空穴。此时携带地层细砂的混合流体会对筛管造成直接的冲蚀,很快导致防砂失效。

关于防砂筛管的评价与选择,目前天然气水合物试采井通常是借鉴石油与天然气工业领域的评价方法,Lee等[76]曾进行了部分绕丝筛管对降压开采水合物井的适应性评价试验。但实际上,绕丝筛管无论从抗堵塞效果还是防砂效果,都未必是最佳的机械防砂筛管,因此, 其应用前景尚需进一步论证。

3.4 完井与储层改造技术

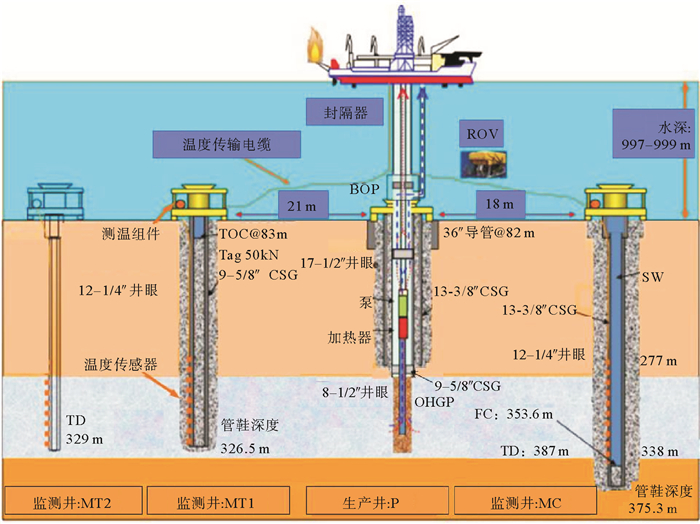

海洋天然气水合物开采完井关键技术主要包括:完井方式优选技术、井下管柱设计方法等,同时也涵盖了3.3小节所述的出砂管理技术。井下管柱的设计重点是完井管柱稳定性分析、生产管柱设计以及井身结构设计,日本2013年天然气水合物试采井管柱设计结果如图 2所示[77];完井方式优选技术需要综合地层出砂程度、试采目标周期等综合考虑[78],目前历次天然气水合物试采中使用的完井方式均不同,Mallik 5L-38(2002)试采井采用“裸眼+机械筛管”完井、Mallik 2L-38(2007)采用套管射孔完井,AT1-P(2013)采用“裸眼+砾石充填”完井,日本2017年试采实施的两口井分别采用先期膨胀GeoForm筛管和井下后期膨胀GeoForm防砂系统完井。因此,目前尚没有统一的天然气水合物试采井完井方式优选技术、完井参数设计方法。

储层改造技术可以弥补由于完井作业造成的高附加表皮的影响。因此,储层改造技术对于分散型海域天然气水合物尤其是超低渗的黏土质粉砂型水合物储层的开采至关重要。如高能气体压裂[79]、超临界CO2压裂技术[80]、机械切割造缝、水力割缝等。上述所有储层改造技术目前研究的焦点是:储层改造技术适应性进行评价(比如评价储层的可压性),优选适合进行改造的储层并对储层改造技术进行技术可行性评价,仍需要做现场试采进行实际验证,才能证明储层改造技术的适应性。

3.5 水合物产气管道流动安全技术

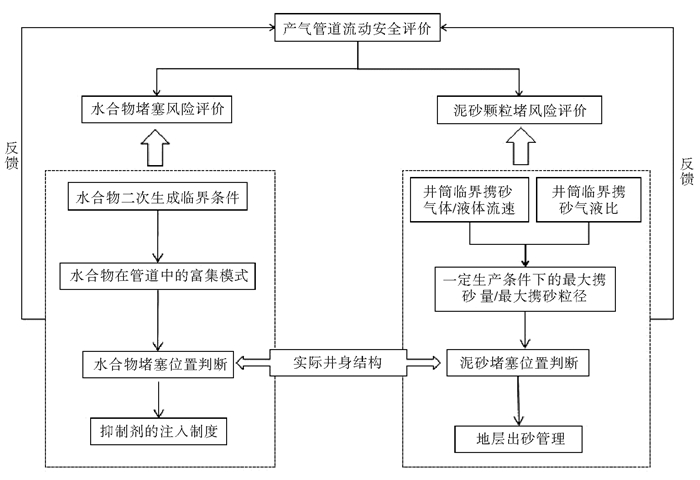

海域天然气水合物试采相关的井筒流动安全主要包括井筒水合物二次生成、井筒携砂条件识别两方面。从水合物二次生成的角度出发,需要首先明确实际生产条件下流动管道内水合物形成的临界条件、临界位置,然后确定水合物在井筒内的富集规律、富集模式,从而判断水合物二次生成对生产影响的极限条件[81],最后制定合理的水合物抑制剂注入方案,从而保证水合物生成管柱正常工作。井筒携砂条件研究的主要目的是防止砂堵和砂沉,防止水合物在砂堵位置处形成,造成砂堵与水合物二次生成的协同效应。具体包括携砂临界气体流速的模拟、携砂临界气液比的模拟、一定气液比条件下的最大携砂粒径模拟和最大携砂量模拟等。与水合物试采相关的产气管道流动安全保障技术基本内容如图 3所示。

3.6 人工举升技术

降压法已经被证明是目前最具应用前景的海域天然气水合物开采方法,但降压开采过程中流入井筒的气、液、固混合流体必须通过一定的举升方式,才能到达平台。因此,举升系统是沟通天然气水合物储层与井口的关键。目前常规深海油气开发过程中用到的人工举升方式电潜泵、螺杆泵、气举等,举升方式的选择与优化是有效延长海域天然气水合物试采周期的必然选择。电潜泵举升是目前海域天然气水合物试采过程中应用较多的举升方式,在日本南海海槽2013年和2017年的两次试采中均得到应用。

随着技术的进步,在举升系统耐砂能力、举升能力等方面都在不断的突破,如目前发展的金属螺杆泵、电潜螺杆泵等新型举升设备等,都可能对水合物试采产生深远影响。也可以通过对已有举升方式的优化设计,实现延长试采周期的目标,如采用双电泵并联举升模式、优化的间歇性气举模式、气举-电泵接力举升等。因此,水合物试采过程中,涉及的人工举升系统目前亟需解决的关键是:评价不同的举升方式对海域天然气水合物,尤其是对我国南海粉砂质水合物储层的适应性,研究不同举升系统的耐受极限,不断研究新的适用于水合物长效开采的举升设备[82]。

另外,由于天然气水合物开采过程中,井筒流动过程为多组分多相混合流动,因此人工举升系统的优选需要考虑气液固三相分离与计量、管道流动安全等内容

3.7 水合物试采多参数监测技术

水合物试采过程中,需要进行试采井多参数的在线监测,具体监测参数包括:试采期间储层及井筒温度的扰动、井筒砂面在线监测、井口流出物测试、举升系统参数监测及海床扰动在线监测等。已经应用到水合物试开采的监测设备主要有中子密度仪、核磁共振仪、温度传感器、压力传感器、超声波仪、电阻仪和色谱仪等。

储层及井筒温度扰动可以通过试采井本身温度传感器的安装实现,也可以再临近监测井中安装温度传感器实现。如日本2013年首次海域天然气水合物试采过程中,在试采井AT1-P中储层中部同时安装电子温度仪、在两口监测井AT1-MC、AT1-MT1中分别安装分布式温度传感器(DTS)电缆和电阻式温度检测器(RTD)阵列,分别测试水合物开采过程中监测井全井段和水合物层的瞬时温度变化。

由于水合物降压开采过程中不可避免地会发生出砂现象,流入井筒的地层砂部分被流体携带至平台井口,部分则在井筒中发生沉积。试采井及监测井中砂面位置动态变化过程的监测,为工程的实时安全评价提供依据。目前常规油气田开采过程中通常采用声测量法和ER监测法进行井筒砂面的动态监测[83],日本2013年AT1-P井试采过程中采用了由井下设备、水下设备、水下-海面设备及海面设备共同构成的砂面监测[84],对监测井进行了长期的观测。因此,针对水合物井筒多相多组分流动特征,研发专用的动态砂面监测系统,为工程实施提供预报,是天然气水合物试采的重要监测数据之一。

井口产出物测试主要包括产出泥砂粒径测试、固相成分测试、气体组分测试、产出液矿化度测试等内容,可能用到的测试仪器如激光粒度测试仪、泥质组分测试仪、气相色谱仪、离子色谱仪等。产出物测试的结果作为水合物分解情况、井筒完整性判断的基本依据,因此,为了满足平台测试需求,配套完整的产出物测试系统,对于水合物试采有重要的意义。

举升系统监测主要是指举升泵系统工况参数的在线传输与记录,在采用电潜泵或螺杆泵举升的情况下,这些参数具体包括实时生产压差、井液温度、泵出/入口压力、泵出口温度、泵运转频率、泵电机电流等,这些参数由泵系统自动记录与传输。另外,举升系统监测数据还应包括井口流量(产气量、产液量、产砂量)、压力(除砂器前压力、除砂器后压力等)数据。

海床扰动监测的主要目的是观察水合物试采过程中引起的海床变形情况。日本2013年AT1-P井试采过程中分别采用三分量加速度传感器、海床式压力传感器进行海床变形监测,美国开发的海床监测系统(Sea-FloorObservatory, SFO)可以同时进行海床变形量、甲烷泄漏量以及表层海床强度参数变化规律的测量,为天然气水合物试采海床扰动监测技术的研发提供了较好的研究思路。

4. 水合物试采实施

目前,国际上对水合物的研究已逐渐从资源勘查转入试采阶段。近十几年,国际上已先后进行了7次天然气水合物试采,其中陆地冻土区4次,海域3次。陆地水合物试采分别为2002年的加拿大麦肯齐三角洲Mallik 5L-38井[46, 47],2007年和2008年的Mallik 2L-38[85, 86],以及2012年的美国阿拉斯加北坡[53, 87]。海域水合物试采分别为2013年和2017年日本南海海槽[88]、2017年中国南海神狐海域。

根据Boswel等[89]的研究结论,目前全球天然气水合物原地资源量中,陆域冻土带水合物资源量约为100s Tcf,海域沉积物水合物资源量约为110 000s Tcf,而其中90%分布在海底黏土质粉砂或淤泥沉积物中。水合物能源金字塔从上往下(图 4),随着水合物储层类型的改变,水合物原地资源量成倍增大,但是资源品味和可采储量所占的比例却降低,因此开采天然气水合物资源的技术难度也迅速增大。截止目前全球范围内典型的天然气水合物资源试采工程在天然气水合物资源金字塔中所处的位置如图 4所示。

上述历次天然气水合物试采对不同的开采技术进行了具体应用,其工程概况对比如表 2所示。其中,2002年采用注热法对Mallik5L-38进行了为期5天的试采,共产出468 m3天然气,最终由于效率和井筒稳定问题停产[90, 91]。2007年采用降压法对Mallik2L-38井进行了试采,在12.5 h内累计产气830 m3,由于没有进行有效的防砂措施,导致地层出砂磨损电潜泵举升设备而停产[46, 47];随后,2008年安装了防砂装置,经过连续6天降压试采,累计产气1.3万m3,充分显示降压法比注热法具有较好的优越性[90]。2012年在美国阿拉斯加北坡采用了二氧化碳置换与降压联合法进行了水合物试采,取得了一定的效果,但模拟分析发现,该次试采产气量大部分贡献来自于降压法,CO2置换对于产能的贡献非常有限[54, 91]。2013年,日本在其南海海槽进行了首次海洋天然气水合物试采,在6天时间内,采用降压法成功采集天然气约12万m3,平均日产达到20 000 m3/天,但最终由于大量出砂,试采被迫终止。2017年6月又进行了第二次降压试采,在20多天的时间里产气20多万立方米,平均达到10 000 m3/天[92];中国在2017年5—7月,在南海神狐海域采用降压法进行首次试采,60天产气30.9万m3,创造了连续稳定产气最长时间记录[93]。

表 2 历次天然气水合物试采产气量对比Table 2. Comparison of gas productivity for previous hydrate exploitation tests年份 所在区域 试采框体 储层类型 试采方法 生产持续时间 累产气量/m3 2002 加拿大麦肯齐三角洲 Mallik site 冻土区砂砾层 注热 5 days 516 2007 降压 12.5 hours 830 2007-2008 降压 139 hours 13 000 2007 阿拉斯加北坡 Mt. Elbert Well 降压 11 hours - 2012 IgnikSikumi CO2置换 6 weeks 24 085 2013 日本南海海槽 第二渥美海丘边缘 海洋中粗砂储层 降压 6 days 120 000 2017(01) 12 days 35 000 2017(02) 24 days 240 000 2017 中国南海北部 神狐海域 海洋黏土质粉砂储层 流体抽取法 60 days 309 000 5. 结论与展望

(1) 数十年的天然气水合物室内模拟研究与场地试采表明,热激法、CO2置换法及化学抑制剂注入法应用于天然气水合物商业开采可能性都不大,只有降压法是简易可行、最有应用前景的开采方法。因此,在未来一段时间内,天然气水合物降压法开采必将是研究重点。降压法与加热法联合,一方面通过降压法在开采初期使水合物快速分解,另一方面通过加热法热量的补充来满足水合物大量分解所需的热量,确保水合物持续高效分解,可弥补降压法开采过程中由于地层温度降低而阻碍水合物持续分解进程甚至造成水合物二次生成的缺陷,是非常值得深入研究的联合开采方法。我国2017年南海神狐海域天然气水合物试采所用的“地层流体抽取法”除了通过抽取地层流体达到降压的目的外,还将较远地层温度较高的流体抽到井筒周围的地层以补充水合物分解所需的热量,起到了降压法与加热法联合应用的效果。可以预计,随着加热技术如电磁加热、微波加热的发展,降压与加热联合法将有广阔的应用前景。

(2) 海域天然气水合物试采成功,标志着对天然气水合物开采技术的研究由室内实验模拟逐步转移到开采关键技术研究上。针对海域天然气水合物降压法开采,一些关键技术如井位优选、降压控制、出砂管理、完井与储层改造、人工举升、管道流动保障及开采多参数监测等尤为重要,是海域天然气水合物试采成功的关键。因此,将室内实验模拟、数值模拟,与试采现场实施紧密结合,开展天然气水合物试采关键技术综合研究,实现室内模拟成果指导现场实践、现场实践证明和修正室内研究成果的有机融合。加强室内模拟、理论建模分析,发展和完善多参数原位/在线监测系统,可以为天然气水合物试采提供有效预警,不断解决试采中的新问题,不断完善试采的各项关键技术。

(3) 如何提高水合物分解效率提升产气能力,缓解大幅度降压带来的大量出砂和储层稳定性难题,是南海粉砂质水合物储层开采面临的主要科学问题。不断进行思路创新、技术创新及装备创新,提出可持续的安全、高效开发方式与开采技术,可能是解决南海天然气水合物开采问题的主要途径。目前采用“直井+简单降压”的方式,很难从量级角度提高天然气水合物井的产能。因此,我们认为:在地层流体抽取法基本前提下,综合“扩大水合物分解面积和压力传递通道”与“设计合理井身结构和防砂方式”,平衡两者关系,开发多途径的高效开发方式,如水平井降压开采技术、降压辅助热力开采技术、改进的SAGD开采技术、双层水平井辅助微波加热降压开采技术、大尺寸主井眼多分支孔有限防砂开采方法等,并配合一定的完井方法和特殊的储层改造技术,将有可能从根本上解决天然气水合物开采的产能约束。

由于海域天然气水合物试采涉及的工程地质问题复杂、成本大、周期长,上述的天然气水合物开发方式及关键技术难以在次数有限的试采工作中进行验证,这就迫切需要室内模拟实验及理论模型的研究,通过仿真模拟及大量的基础研究,才能促进这些开发方式的现场应用,从而推动天然气水合物的产业化进程。

-

图 1 天然气水合物开采方法示意图[2]

(ΔP:降压法;ΔT:热激发法;ΔP+ ΔT:降压法+热激法;向左、上蓝色箭头:化学抑制剂注入法;绿色阴影部分:CO2置换法)

Figure 1. Schematic digram of commonly proposed gas recovery methods

表 1 天然气水合物试采和出砂与防砂情况

Table 1 Overview of sand production and sand mamagement status during hydrate exploitation

试采井位 防砂方式 效果 加拿大Mallik 5L-38(2002) 防砂机械筛管防砂 有砂产出 加拿大Mallik 2L-38(2007) 射孔完井,未防砂 出砂造成ESP损坏 加拿大Mallik 2L-38(2008) 机械筛管防砂;泵入口加防砂网 有砂产出 美国阿拉斯加(2012) 机械筛管防砂 有砂产出 日本AT1-P(2013) 裸眼砾石充填防砂 出砂造成ESP损坏,试采终止 日本2017-001* 先期膨胀GeoForm筛管 防砂失败,井筒砂埋 日本2017-002* 井下膨胀GeoForm筛管 效果较好 *日本2017年海域天然气水合物试采两口井的具体站位数据目前暂未见报道,因此, 采用2017-001、2017-002代替。 表 2 历次天然气水合物试采产气量对比

Table 2 Comparison of gas productivity for previous hydrate exploitation tests

年份 所在区域 试采框体 储层类型 试采方法 生产持续时间 累产气量/m3 2002 加拿大麦肯齐三角洲 Mallik site 冻土区砂砾层 注热 5 days 516 2007 降压 12.5 hours 830 2007-2008 降压 139 hours 13 000 2007 阿拉斯加北坡 Mt. Elbert Well 降压 11 hours - 2012 IgnikSikumi CO2置换 6 weeks 24 085 2013 日本南海海槽 第二渥美海丘边缘 海洋中粗砂储层 降压 6 days 120 000 2017(01) 12 days 35 000 2017(02) 24 days 240 000 2017 中国南海北部 神狐海域 海洋黏土质粉砂储层 流体抽取法 60 days 309 000 -

[1] Bonnefoy O, Gruy F, Herri J M, et al. Interactions in systems involving gas hydrates[J]. Fluid Phase Equilibria, 2005, 231(2): 176-187. doi: 10.1016/j.fluid.2005.02.004

[2] Chong Z R, Yang S H B, Babu P, et al. Review of natural gas hydrates as an energy resource: Prospects and challenges[J]. Applied Energy, 2016, 162: 1633-1652. doi: 10.1016/j.apenergy.2014.12.061

[3] Yousif M H, Abass H H, Selim M S, et al. Experimental and theoretical investigation of methane-gas-hydrate dissociation in porous media[J]. SPE Reservoir Engineering, 1991, 6(1): 69-76. doi: 10.2118/18320-PA

[4] Booth J S, Winters W J, and Dillon W P. Apparatus investigates geological aspects of gas hydrates[J]. Oil and Gas Journal, 1999, 8(4): 63-70. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bc017fb80a21d48dd8e0624f786be8bf

[5] Phelps T J, Peters D J, Marshall S L, et al. A new experimental facility for investigating the formation and properties of gas hydrates under simulated seafloor conditions[J]. Review of Scientific Instruments, 2001, 72(2): 1514-1521. doi: 10.1063/1.1334628

[6] Kono H O, Narasimhan S, Song F, et al. Synthesis of methane gas hydrate in porous sediments and its dissociation by depressurizing[J]. Powder Technology, 2002, 122(2-3): 239-246. doi: 10.1016/S0032-5910(01)00420-X

[7] Charles E T. Large-volume, high-pressure view vell helps fill gaps in understanding of methane hydrate behavior[Z]. Fire in the Ice Newsletter, Summer. USA: The National Energy Technology Laboratory, 2004: 10-12.

[8] Linga P C, Haligva S C, Nam J A, et al. Recovery of methane from hydrate formed in a variable volume bed of silica sand particles[J]. Energy and Fuels, 2009, 23(11): 5508-5516. doi: 10.1021/ef900543v

[9] 孙建业, 业渝光, 刘昌岭, 等.沉积物中天然气水合物减压分解实验[J].现代地质, 2010, 24(3): 614-621. doi: 10.3969/j.issn.1000-8527.2010.03.028 SUN Jianye, YE Yuguang, LIU Changling, et al. Experimental research of gas hydrate dissociation in sediments by depressurization method[J]. Geoscience, 2010, 24(3): 614-621. doi: 10.3969/j.issn.1000-8527.2010.03.028

[10] 唐良广, 肖睿, 李刚, 等.热力法开采天然气水合物的模拟实验研究[J].过程工程学报, 2006, 6(4): 548-553. doi: 10.3321/j.issn:1009-606X.2006.04.007 TANG Liangguang, XIAO Rui, LI Gang, et al. Experimental investigation of production behavior of gas hydrate under thermal stimulation[J]. The Chinese Journal of Process Engineering, 2006, 6(4): 548-553. doi: 10.3321/j.issn:1009-606X.2006.04.007

[11] 李淑霞, 徐新华, 吴锦谨, 等.不同注热水温度下水合物开采实验研究[J].现代地质, 2013, 27(6): 1379-1383. doi: 10.3969/j.issn.1000-8527.2013.06.015 LI Shuxia, XU Xinhua, WU Jinjin, et al. Experimental investigation of gas hydrate dissociation by hot brine injection with different temperatures[J]. Geoscience, 2013, 27(6): 1379-1383. doi: 10.3969/j.issn.1000-8527.2013.06.015

[12] 梁海峰.多孔介质中甲烷水合物降压分解实验与数值模拟[D].大连: 大连理工大学博士学位论文, 2009. LIANG Haifeng. Experimental and numerical study of methane hydrate dissociation by depressurization in porous media[D]. Dalian: Doctoral Dissertation of Dalian University of Technology, 2009.

[13] 刘乐乐, 鲁晓兵, 张旭辉.砂土沉积物中甲烷水合物降压分解渗流阵面实验[J].天然气工业, 2013, 33(11): 130-136. doi: 10.3787/j.issn.1000-0976.2013.11.023 LIU Lele, LU Xiaobing, ZHANG Xuhui. An experimental study of seepage front due to methane hydrate dissociation by depressurization in sandy sediments[J]. Natural Gas Industry, 2013, 33(11): 130-136. doi: 10.3787/j.issn.1000-0976.2013.11.023

[14] Li X S, Yang B, Li G, et al. Experimental study on gas production from methane hydrate in porous media by huff and puff method in Pilot-Scale Hydrate Simulator[J]. Fuel, 2012, 94: 486-494. doi: 10.1016/j.fuel.2011.11.011

[15] 粟科华, 孙长宇, 李楠, 等.天然气水合物三维成藏物模实验系统的构建与检验[J].天然气工业, 2013, 33(12): 173-178. http://d.old.wanfangdata.com.cn/Periodical/trqgy201312027 SU Kehua, SUN Changyu, LI Nan, et al. A large-scale three-dimensional device for simulating natural gas hydrates accumulation and distribution process in sediments[J]. Natural Gas Industry, 2013, 33(12): 173-178. http://d.old.wanfangdata.com.cn/Periodical/trqgy201312027

[16] Nagao J, Konno Y. Development of large scale production system for methane hydrates[C]// Proceedings of the Tenth ISOPE Ocean Mining and Gas Hydrates Symposium. Szczecin, Poland: International Society of Offshore and Polar Engineers, 2013.

[17] Spangenberg E, Priegnitz M, Heeschen K, et al. How close are laboratory formed pore-filling hydrate systems to nature[C]//Proceedings of the 8th International Conference on Gas Hydrates. Beijing, China, 2014.

[18] Yousif M H, Sloan E D. Experimental investigation of hydrate formation and dissociation in consolidated porous media[J]. SPE Reservoir Engineering, 1991, 6(4): 452-458. doi: 10.2118/20172-PA

[19] Li X S, Xu C G, Zhang Y, et al. Investigation into gas production from natural gas hydrate: A review[J]. Applied Energy, 2016, 172: 286-322. doi: 10.1016/j.apenergy.2016.03.101

[20] Zhou Y, Castaldi M J, Yegulalp T M. Experimental investigation of methane gas production from methane hydrate[J]. Industrial & Engineering Chemistry Research, 2009, 48(6): 3142-3149. doi: 10.1021/ie801004z

[21] Tang L G, Li X S, Feng Z P, et al. Control mechanisms for gas hydrate production by depressurization in different scale hydrate reservoirs[J]. Energy Fuels 2007, 21(1): 227-233. doi: 10.1021/ef0601869

[22] 孙建业.海洋沉积物中天然气水合物开采实验研究[D].青岛: 中国海洋大学博士学位论文, 2011. SUN Jianye. Experimental research of gas hydrates exploitation in marine sediments[D]. Qingdao: Doctoral Dissertation of Ocean University of China, 2011.

[23] Taewoong A, Lee J, Lee J Y, et al. Depresurization-induced production behavior of methane hydrate in a meter-scale alternate layer of sand and mud[C]//Proceedings of the 9th International Conference on Gas Hydrates. Denver, Colorado, USA, 2017.

[24] Sakamoto Y, Komai T, Kawabe Y, et al. Gas hydrate extraction from marine sediments by heat stimulation method[C]//The Fourteenth International Offshore and Polar Engineering Conference. Toulon: International Society of Offshore and Polar Engineers, 2004: 52-55.

[25] Castaldi M J, Zhou Y, Yegulalp T M. Down-hole combustion method for gas production from methane hydrates[J]. Journal of Petroleum Science and Engineering, 2007, 56(1-3): 176-185. doi: 10.1016/j.petrol.2006.03.031

[26] 李栋梁, 樊栓狮.微波作用下天然气水合物分解的研究及应用[J].化工进展, 2003, 22(3): 280-282. doi: 10.3321/j.issn:1000-6613.2003.03.013 LI Dongliang, FAN Shuanshi. Research on natural gas hydrate with microwave and its application[J]. Chemical Industry and Engineering Progress, 2003, 22(3): 280-282. doi: 10.3321/j.issn:1000-6613.2003.03.013

[27] Handa Y P, Stupin D. Thermodynamic properties and dissociation characteristics of methane and propane hydrates in 70~?~radius silica gel pore[J]. The Journal of Physical Chemistry, 1992, 96(21): 8599-8603. doi: 10.1021/j100200a071

[28] Li S X, Wang Z Q, Xu X H, et al. Experimental study on dissociation of hydrate reservoirs with different saturations by hot brine injection[J]. Journal of Natural Gas Science and Engineering, 2017, doi: 10.1016/j.jngse.2017.07.032.

[29] 孙建业, 业渝光, 刘昌岭, 等.沉积物中天然气水合物合成及开采模拟实验研究[J].中国海洋大学学报:自然科学版, 2009, 39(6): 1289-1294. doi: 10.3969/j.issn.1672-5174.2009.06.017 SUN Jianye, YE Yuguang, LIU Changling, et al. Simulation experiment of gas hydrates formation and exploitation in sediments[J]. Periodical of Ocean University of China, 2009, 39(6): 1289-1294. doi: 10.3969/j.issn.1672-5174.2009.06.017

[30] Fan S S, Zhang Y Z, Tian G L, et al. Natural gas hydrate dissociation by presence of ethylene glycol[J]. Energy and Fuels 2005, 20(1): 324-326. doi: 10.1021/ef0502204

[31] Ruppel C, Dickens G R, Castellini, D G, et al. Heat and salt inhibition of gas hydrate formation in the northern Gulf of Mexico[J]. Geophysical Research Letters, 2005, 32(4): L04605. doi: 10.1029/2004gl021909

[32] Dong F H, Zang X Y, Li D L, et al. Experimental investigation on propane hydrate dissociation by high concentration methanol and ethylene glycol solution injection[J]. Energy and Fuels, 2009, 23(3): 1563-1567. doi: 10.1021/ef800660m

[33] Sira J H, Patil S L, Kamath V A. Study of hydrate dissociation by methanol and glycol injection[C]//SPE Annual Technical Conference and Exhibition. New Orleans, Louisiana: Society of Petroleum Engineers, 1990: 977-984.

[34] Lee J. Experimental study on the dissociation behavior and productivity of gas hydrate by brine injection scheme in porous rock[J]. Energy and Fuels, 2009, 24(1): 456-463.

[35] Bhattacharjee G, Barmecha V, Pandey N K, et al. A study of natural gas hydrate dissociation in the presence of novel benign additives[C]//Proceedings of the 9th International Conference on Gas Hydrates. Denver, Colorado, USA, 2017.

[36] Ota M, Abe Y, Watanabe M, et al. Methane recovery from methane hydrate using pressurized CO2[J]. Fluid Phase Equilibria, 2005, 228-229: 553-559. doi: 10.1016/j.fluid.2004.10.002

[37] McGrail B P, Zhu T, Hunter R B, et al. A new method for enhanced production of gas hydrates with CO2[C]//AAPG Hedberg Conference: "Gas Hydrates: Energy Resource Potential and Associated Geologic Hazards". Vancouver, BC: AAPG, 2004.

[38] Schicks J M. From lab to field, from micro to macro-test of technologies for the production of hydrate bonded CH4 via CO2 sequestration in hydrates[C]//Proceedings of the 9th International Conference on Gas Hydrates. Denver, Colorado, USA, 2017.

[39] Lee Y, Seo Y. Experimental verification of CH4-CO2 or CH4-flue gas replacementthat occurs in various gas hydrate structures[C]//Proceedings of the 9th International Conference on Gas Hydrates. Denver, Colorado, USA, 2017.

[40] Ota M. Replacement of CH4 in the hydrate by use of liquid CO2[J]. Energy Conversion and Management, 2005, 46(11-12): 1680-1691. doi: 10.1016/j.enconman.2004.10.002

[41] He Y, Rudolph E S J, Zitha P L J, et al. Recovery of methane hydrates by CO2 injection: experimental investigation[C]//Proceedings of the 7th International Conference on Gas Hydrates. United Kingdom, 2011.

[42] Masuda Y, Maruta H, Naganawa S, et al. Methane recovery from hydrate-bearing sediments by N2-CO2 gas mixture injection: experimental investigation on CO2-CH4 exchange ratio[C]//Proceedings of the 7th International Conference on Gas Hydrates. United Kingdom, 2011.

[43] 孙建业, 刘乐乐, 王小文, 等.沉积物中甲烷水合物的CO2置换实验[J].天然气工业, 2015, 35(8): 56-62. doi: 10.3787/j.issn.1000-0976.2015.08.008 SUN Jianye, LIU Lele, WANG Xiaowen, et al. Experimental study on the replacement of methane hydrate in sediments with CO2[J]. Natural Gas Industry, 2015, 35(8): 56-62. doi: 10.3787/j.issn.1000-0976.2015.08.008

[44] 沈志远, 冯自平, 唐良广, 等.海洋渗漏型天然气水合物气力提升特性模型分析[J].能源工程, 2007(2): 17-20. doi: 10.3969/j.issn.1004-3950.2007.02.004 SHEN Zhiyuan, FENG Ziping, TANG Liangguang, et al. Modeling studies on the production process of offshore seepage gas hydrate by airlifting[J]. Energy Engineering, 2007(2): 17-20. doi: 10.3969/j.issn.1004-3950.2007.02.004

[45] 张旭辉, 鲁晓兵, 刘乐乐.天然气水合物开采方法研究进展[J].地球物理学进展, 2014, 29(2): 858-869. doi: 10.6038/pg20140252 ZHANG Xuhui, LU Xiaobing, LIU Lele. Advances in natural gas hydrate recovery methods[J]. Process in Geophysics, 2014, 29(2): 858-869. doi: 10.6038/pg20140252

[46] Dong H, Wu K S, Wu B, et al. Modular production system with decomposing natural gas hydrate and separating the sediments from NGH slurry on seabed[C]//Proceedings of the 9th International Conference on Gas Hydrates. Denver, Colorado, USA, 2017.

[47] Dallimore S R, Collett T S. Scientific Results from the Mallik 2002 Gas Hydrate Production Research Well Program, Mackenzie Delta, Northwest Territories, Canada[M]. Geological Survey of Canada, 2005.

[48] Anderson B I, Collett T S, Lewis R E, et al. Using open hole and cased-hole resistivity logs to monitor gas hydrate dissociation during a thermal test in the Mallik 5L-38 research well, Mackenzie Delta, Canada[J]. Petrophysics, 2008, 49(3): 285-294. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cadca00a017911bc2196dc18e1cde5f8

[49] Kurihara M, Funatsu K, Ouchi H, et al. Analysis of the JOGMEC/NRCan/Aurora Mallik gas hydrate production test through numerical simulation[C]//Proceedings of the 6th International Conference on Gas Hydrates. Vancouver, British Columbia, Canada, 2008.

[50] Cyranoski D. Japanese test coaxes fire from ice[J]. Nature, 2013, 496(7446): 409. doi: 10.1038/496409a

[51] Takahashi H, Yonezawa T, Fercho E. Operation overview of the 2002 Mallik gas hydrate production research well program at the Mackenzie Delta in the Canadian Arctic[C]//Proceedings of the Offshore Technology Conference. Houston, Texas, USA: Offshore Technology Conference, 2003.

[52] Collett T S, Lewis R E, Winters W F, et al. Downhole well log and core montages from the Mount Elbert gas hydrate stratigraphic test well, Alaska North Slope[J]. Journal of Marine and Petroleum Geology, 2011, 28(2): 561-577. doi: 10.1016/j.marpetgeo.2010.03.016

[53] Kvamme B. Feasibility of simultaneous CO2 storage and CH4 production from natural gas hydrate using mixtures of CO2 and N2[J]. Canadian Journal of Chemistry, 2015, 93(8): 897-905. doi: 10.1139/cjc-2014-0501

[54] Song Y C, Cheng C X, Zhao J F, et al. Evaluation of gas production from methane hydrates using depressurization, thermal stimulation and combined methods[J]. Applied Energy, 2015, 145: 265-277. doi: 10.1016/j.apenergy.2015.02.040

[55] Falser S, Uchida S, Palmer A C, et al. Increased gas production from hydrates by combining depressurization with heating of the wellbore[J]. Energy and Fuels, 2012, 26(10): 6259-6267. doi: 10.1021/ef3010652

[56] Kurihara M, Sato A, Ouchi H, et al. Prediction of gas productivity from eastern Nankai Trough methane-hydrate reservoirs[C]//Offshore Technology Conference 2008. Houston, Texas, USA: Offshore Technology Conference, 2008.

[57] Moridis G J. Numerical studies of gas production from methane hydrates[J]. SPE Journal, 2003, 8(4): 359-370. doi: 10.2118/87330-PA

[58] Moridis G J, Collett T S, Dallimore S R, et al. Numerical studies of gas production from several CH4 hydrate zones at the Mallik site, Mackenzie Delta, Canada[J]. Journal of Petroleum Science and Engineering, 2004, 43(3-4): 219-238. doi: 10.1016/j.petrol.2004.02.015

[59] Myshakin E M, Ajayi T, Anderson B J, et al. Anderson Numerical simulations of depressurization-induced gas production from gas hydrates using 3-D heterogeneous models of L-Pad, Prudhoe Bay Unit, North Slope Alaska[J]. Journal of Natural Gas Science and Engineering, 2016, 35: 1336-1352. doi: 10.1016/j.jngse.2016.09.070

[60] 苏正, 吴能友, 张可霓.南海北部陆坡神狐天然气水合物开发潜力[J].海洋地质前沿, 2011(6): 16-23. http://d.old.wanfangdata.com.cn/Conference/8138063 SU Zheng, WU Nengyou, ZHANG Keni. Assessment of gas production potential of hydrate deposits at Shenhu area on northern continental slope of South China Sea[J]. Marine Geology Letters, 2011(6): 16-23. http://d.old.wanfangdata.com.cn/Conference/8138063

[61] 苏正, 何勇, 吴能友.南海北部神狐海域天然气水合物热激发开采潜力的数值模拟分析[J].热带海洋学报, 2012, 31(5): 74-82. doi: 10.3969/j.issn.1009-5470.2012.05.011 SU Zheng, HE Yong, WU Nengyou. Numerical simulation on production potential of hydrate deposits by thermal stimulation[J]. Journal of Tropical Oceanography, 2012, 31(5): 74-82. doi: 10.3969/j.issn.1009-5470.2012.05.011

[62] Jin G R, Xu T F, Xin X, et al. Numerical evaluation of the methane production from unconfined gashydrate-bearing sediment by thermal stimulation and depressurization in Shenhu area, South China Sea[J]. Journal of Natural Gas Science and Engineering, 2016, 33: 497-508. doi: 10.1016/j.jngse.2016.05.047

[63] Sun J X, Ning F L, Li S, et al. Numerical simulation of gas production from hydrate- bearing sediments[J]. Journal of Unconventional Oil and Gas Resources, 2015, 12: 23-33. doi: 10.1016/j.juogr.2015.08.003

[64] [65] Collett T S, Boswell R M. Gas Hydrate Research Site Selection and Operational Research Plans[M]. Washington, DC: American Geophysical Union, 2009.

[66] Fujii T, Noguchi S, Takayama T, et al. Site selection and formation evaluation at the 1st offshore methane hydrate production test site in the eastern Nankai Trough, Japan[C]//75th EAGE Conference and Exhibition., London, UK: EAGE, 2013.

[67] Heeschen K U, Abendroth S, Priegnitz M, et al. Gas production from methane hydrate: a laboratory simulation of the multistage depressurization test in mallik, Northwest Territories, Canada[J]. Energy and Fuels, 2016, 30(8): 6210-6219. doi: 10.1021/acs.energyfuels.6b00297

[68] Terao Y, Lay K, Yamamoto K. Design of the surface flow test system for 1st offshore production test of methane hydrate[C]//Offshore Technology Conference-Asia 2014. Kuala Lumpur, Malaysia: Offshore Technology Conference, 2014.

[69] Uchida S, Klar A, Yamamoto K. Sand production model in gas hydrate-bearing sediments[J]. International Journal of Rock Mechanics and Mining Sciences, 2016, 86: 303-316. doi: 10.1016/j.ijrmms.2016.04.009

[70] Terao Y, Lay K, Yamamoto K. Design of the surface flow test system for 1st offshore production test of methane hydrate[C]//Offshore Technology Conference-Asia 2014. Kuala Lumpur, Malaysia: Offshore Technology Conference, 2014.

[71] 李彦龙, 刘乐乐, 刘昌岭, 等.天然气水合物开采过程中的出砂与防砂问题[J].海洋地质前沿, 2016, 32(7): 36-43. doi: 10.16028/j.1009-2722.2016.07005 LI Yanlong, LIU Lele, LIU Changling, et al. Sanding prediction and sand-control technology in hydrate exploitation: a review and discussion[J]. Marine Geology Frontiers, 2016, 32(7): 36-43. doi: 10.16028/j.1009-2722.2016.07005

[72] Uchida S, Klar A, Charas Z, et al. Thermo-hydro-mechanical sand production model in hydrate-bearing sediments[C]//EAGE International Workshop on Geomechanics and Energy-The Ground as Energy Source and Storage. Lausanne, Switzerland: EAGE, 2013.

[73] Sun J X, Zhang L, Ning F L, et al. Production potential and stability of hydrate-bearing sediments at the site GMGS3-W19 in the South China Sea: A preliminary feasibility study[J]. Marine and Petroleum Geology, 2017, 86: 447-473. doi: 10.1016/j.marpetgeo.2017.05.037

[74] Lee J, Ahn T, Lee J Y, et al. Laboratory test to evaluate the performance of sand control screens during hydrate dissociation process by depressurization[C]//Proceedings of the Tenth ISOPE Ocean Mining and Gas Hydrates Symposium. Szczecin, Poland: International Society of Offshore and Polar Engineers, 2013.

[75] Yamamoto K, Terao Y, Fujii T, et al. Operational overview of the first offshore production test of methane hydrates in the eastern Nankai Trough[C]//Offshore Technology Conference 2014. Houston, Texas: Offshore Technology Conference, 2014.

[76] Yoneda J, Kakumoto M, Miyazaki K, et al. Evaluation of frictional properties for methane-hydrate-well completion and production[J]. SPE Drilling and Completion, 2014, 29(1): 115-124. doi: 10.2118/169897-PA

[77] 祝道平, 宁正福.利用高能气体压裂技术开采天然气水合物可行性分析[J].重庆科技学院学报:自然科学版, 2009, 11(3): 37-39. doi: 10.3969/j.issn.1673-1980.2009.03.011 ZHU Daoping, NING Fuzheng. High-energy gas fracturing technique to exploit natural gas hydrate reservoir[J]. Journal of Chongqing University of Science and Technology: Natural Sciences Edition, 2009, 11(3): 37-39. doi: 10.3969/j.issn.1673-1980.2009.03.011

[78] 孙小辉, 孙宝江, 王志远.超临界CO2压裂裂缝温度场模型[J].石油学报, 2015, 36(12): 1586-1592. doi: 10.7623/syxb201512014 SUN Xiaohui, SUN Baojiang, WANG Zhiyuan. Fissure temperature field model of supercritical CO2 fracturing[J]. Acta Pretrolei Sinica, 2015, 36(12): 1586-1592. doi: 10.7623/syxb201512014

[79] Seol Y, Myshakin E. Experimental and numerical observations of hydrate reformation during depressurization in a core-scale reactor[J]. Energy and Fuels, 2011, 25(3): 1099-1110. doi: 10.1021/ef1014567

[80] Liu Z J, Zerpa L E. Preliminary study of liquid loading problems for gas hydrate wells and selection of artificial lift methods[C]//SPE Western Regional Meeting. Anchorage, Alaska, USA: Society of Petroleum Engineers, 2016.

[81] 隋秀香, 郭旗, 李相方.油气井测试出砂监测技术[J].天然气工业, 2004, 24(5): 110-112. doi: 10.3321/j.issn:1000-0976.2004.05.036 SUI Xiuxiang, GUO Qi, LI Xiangfang. Sand production monitoring techniques of oil and gas wells[J]. Natural Gas Industry, 2004, 24(5): 110-112. doi: 10.3321/j.issn:1000-0976.2004.05.036

[82] Wilson A. System monitors sandface for deepwater offshore gas-hydrate production[J]. Journal of Petroleum Technology, 2014, 66(9): 102-105. doi: 10.2118/0914-0102-JPT

[83] Kurihara M, Sato A, Funatsu K, et al. Analysis of production data for 2007/2008 mallik gas hydrate production tests in Canada[C]//International Oil & Gas Conference & Exhibition in China. Beijing: Society of Petroleum Engineers, 2010.

[84] Dubreuil-Boisclair C, Gloaguen E, Bellefleur G, et al. Non-Gaussian gas hydrate grade simulation at the Mallik site, Mackenzie Delta, Canada[J]. Marine and Petroleum Geology, 2012, 35(1): 20-27. doi: 10.1016/j.marpetgeo.2012.02.020

[85] Schoderbek D, Farrell H, Hester K, et al. Conoco- Phillips gas hydrate production test final technical report[R]. United States Department of Energy, 2013.

[86] Nagao J, Jin Y, Konno Y, et al. Characterization of sediment cores containing methane hydrate recovered from the Eastern Nankai Trough[C]//AGU Fall Meeting Abstracts. Washington, DC: AGU, 2013.

[87] Boswell R, Collett T S. Current perspectives on gas hydrate resources[J]. Energy and Environmental Science, 2011, 4(4): 1206-1215. doi: 10.1039/C0EE00203H

[88] Haberer R M, Kai M, Wilkes H, et al. Occurrence and palaeoenvironmental significance of aromatic hydrocarbon biomarkers in Oligocene sediments from the Mallik 5L-38 Gas Hydrate Production Research Well (Canada)[J]. Organic Geochemistry, 2006, 37(5): 519-538. doi: 10.1016/j.orggeochem.2006.01.004

[89] Hancock S H, Collett T S, Dallimore S R, et al. Overview of thermal-stimulation production-test results for the JAPEX/JNOC/GSC et al. Mallik 5L-38 Gas Hydrate Production Research Well[M]. Dallimore S R, Collett T S. Scientific Results from the Mallik 2002 Gas Hydrate Production Research Well Program, Mackenzie Delta, Northwest Territories, Canada. Geological Survey of Canada, 2005.

[90] Hunter R B, Collett T S, Boswell R, et al. Mount Elbert gas hydrate stratigraphic test well, Alaska north slope: overview of scientific and technical program[J]. Marine and Petroleum Geology, 2011, 28(2): 295-310. doi: 10.1016/j.marpetgeo.2010.02.015

[91] Collett T, Bahk J J, Frye M, et al. Historical methane hydrate project review[R]. 2013.

[92] http://www.meti.go.jp/press/2017/06/20170629004/20170629004.html.

[93] -

期刊类型引用(40)

1. 周瑞,白冰,杨光昌. 基于颗粒重组理论的水合物沉积物温-压耦合热力学模型. 岩土工程学报. 2024(06): 1226-1235 .  百度学术

百度学术

2. 徐鸿志,宋伟宸,步玉环,向常友,柳华杰,路畅. 基于水合物层骨架重构的低温早强胶凝材料. 钻井液与完井液. 2024(03): 357-363 .  百度学术

百度学术

3. 孙振鑫,王亚楠,李清平,吕鑫,葛阳. 自生热体系开采天然气水合物效果评价. 当代化工. 2023(01): 77-81 .  百度学术

百度学术

4. 冯明,李淑霞,郭洋,赵凤锐. 天然气水合物试采监测井技术研究进展. 当代化工研究. 2023(03): 22-24 .  百度学术

百度学术

5. 孙华忠,李忠慧,熊青山,唐川富,王晓燕,李玉波. 分解促进剂对水合物力学的特性影响分析. 石油与天然气化工. 2023(06): 66-73 .  百度学术

百度学术

6. 欧芬兰,于彦江,寇贝贝,陈靓. 水合物藏的类型、特点及开发方法探讨. 海洋地质与第四纪地质. 2022(01): 194-213 .  本站查看

本站查看

7. 张吉东,刘晓惠,边培明,吴强,殷振元. 含水合物沉积物孔隙流动特性数值模拟. 中南大学学报(自然科学版). 2022(03): 855-863 .  百度学术

百度学术

8. 卢静生,吴思婷,李栋梁,梁德青,魏伟,何勇,史伶俐,邓福成,熊友明. 海洋天然气水合物开采的固相控制策略. 新能源进展. 2022(02): 137-145 .  百度学术

百度学术

9. Yanlong Li,Nengyou Wu,Changling Liu,Qiang Chen,Fulong Ning,Shuoshi Wang,Gaowei Hu,Deli Gao. Hydrate formation and distribution within unconsolidated sediment: Insights from laboratory electrical resistivity tomography. Acta Oceanologica Sinica. 2022(09): 127-136 .  必应学术

必应学术

10. 王磊,杨进,李莅临,胡志强,柯珂,臧艳彬,孙挺. 深水含水合物地层钻井井口稳定性研究. 岩土工程学报. 2022(12): 2312-2318 .  百度学术

百度学术

11. 毛佩筱,吴能友,万义钊,陈强,胡高伟. 多分支井射孔程度和布设位置对倾斜泥质水合物储层开采产能的影响. 海洋地质与第四纪地质. 2022(06): 207-217 .  本站查看

本站查看

12. 刘乐乐,刘昌岭,吴能友,阮海龙,张永超,郝锡荦,卜庆涛. 天然气水合物储层岩心保压转移与测试进展. 地质通报. 2021(Z1): 408-422 .  百度学术

百度学术

13. 孙嘉鑫,赵洪宝,曹鑫鑫,毛佩筱. 南海荔湾区域水合物水平井降压开采模拟研究. 科学技术与工程. 2021(24): 10246-10256 .  百度学术

百度学术

14. 杨德欢,颜梦秋,陆地,颜荣涛,韦昌富,田慧会. 含天然气水合物土水-力特性联合测试装置及应用. 工程地质学报. 2021(06): 1722-1732 .  百度学术

百度学术

15. 夏志增,王学武,时凤霞,郭瑾. 热水驱替开采Ⅱ类水合物藏规律研究. 海洋地质与第四纪地质. 2020(02): 158-164 .  本站查看

本站查看

16. 宁伏龙,方翔宇,李彦龙,窦晓峰,王林杰,刘志超,罗强,孙嘉鑫,赵颖杰,张准,刘天乐,张凌,蒋国盛. 天然气水合物开采储层出砂研究进展与思考. 地质科技通报. 2020(01): 137-148 .  百度学术

百度学术

17. 吴能友,李彦龙,万义钊,孙建业,黄丽,毛佩筱. 海域天然气水合物开采增产理论与技术体系展望. 天然气工业. 2020(08): 100-115 .  百度学术

百度学术

18. 陈强,胡高伟,李彦龙,万义钊,刘昌岭,吴能友,刘洋. 海域天然气水合物资源开采新技术展望. 海洋地质前沿. 2020(09): 44-55 .  百度学术

百度学术

19. 刘乐乐,刘昌岭,孟庆国,张永超. 分形理论在天然气水合物研究领域的应用. 海洋地质前沿. 2020(09): 11-22 .  百度学术

百度学术

20. 张永超,刘昌岭,吴能友,刘乐乐,郝锡荦,孟庆国,李承峰,孙建业,王代刚. 含水合物沉积物孔隙结构特征与微观渗流模拟研究. 海洋地质前沿. 2020(09): 23-33 .  百度学术

百度学术

21. 李莅临,杨进,路保平,柯珂,王磊,陈柯锦. 深水水合物试采过程中地层沉降及井口稳定性研究. 石油钻探技术. 2020(05): 61-68 .  百度学术

百度学术

22. 李彦龙,陈强,刘昌岭,吴能友,孙建业,申志聪,张民生,胡高伟. 水合物储层工程地质参数评价系统研发与功能验证. 海洋地质与第四纪地质. 2020(05): 192-200 .  本站查看

本站查看

23. 毛佩筱,吴能友,宁伏龙,胡高伟,孙嘉鑫,陈强,郭洋,卜庆涛,万义钊. 不同井型下的天然气水合物降压开采产气产水规律. 天然气工业. 2020(11): 168-176 .  百度学术

百度学术

24. 何家雄,钟灿鸣,姚永坚,阎贫,王彦林,万志峰,关雎,张金峰. 南海北部天然气水合物勘查试采及研究进展与勘探前景. 海洋地质前沿. 2020(12): 1-14 .  百度学术

百度学术

25. 张金华,樊波,刘瑞江. 天然气水合物钻探现状与钻井技术. 科学技术与工程. 2020(35): 14343-14351 .  百度学术

百度学术

26. 李守定,孙一鸣,陈卫昌,于志全,周忠鸣,刘丽楠,赫建明,张召彬,李晓. 天然气水合物开采方法及海域试采分析. 工程地质学报. 2019(01): 55-68 .  百度学术

百度学术

27. 刘昌岭,李彦龙,刘乐乐,胡高伟,陈强,吴能友,孟庆国. 天然气水合物钻采一体化模拟实验系统及降压法开采初步实验. 天然气工业. 2019(06): 165-172 .  百度学术

百度学术

28. 沙志彬,许振强,付少英,梁金强,张伟,苏丕波,陆红锋,陆敬安. 珠江口盆地东部海域天然气水合物成藏气源特征探讨. 海洋地质与第四纪地质. 2019(04): 116-125 .  本站查看

本站查看

29. 卢静生,熊友明,李栋梁,梁德青,金光荣,何勇,申小冬. 非成岩水合物储层降压开采过程中出砂和沉降实验研究. 海洋地质与第四纪地质. 2019(04): 183-195 .  本站查看

本站查看

30. 黄芳飞,张旗,何涛,陆红锋,陈爱华. 海域天然气水合物监测井技术进展与挑战. 科学技术与工程. 2019(27): 21-30 .  百度学术

百度学术

31. 李彦龙,孙海亮,孟庆国,刘昌岭,陈强,邢兰昌. 沉积物中天然气水合物生成过程的二维电阻层析成像观测. 天然气工业. 2019(10): 132-138 .  百度学术

百度学术

32. 孙志豪,郭子东,陈俊,陆星洲,魏凤玉. 哌嗪类有机胺脱除二氧化硫性能及机理探讨. 化工进展. 2019(11): 46-51 .  百度学术

百度学术

33. Jingchun Feng,Longtao Sun,Yi Wang,Xiaosen Li. Advances of experimental study on gas production from synthetic hydrate reservoir in China. Chinese Journal of Chemical Engineering. 2019(09): 2213-2225 .  必应学术

必应学术

34. Fengguang Li,Qing Yuan,TiANDuo Li,Zhi Li,Changyu Sun,Guangjin Chen. A review: Enhanced recovery of natural gas hydrate reservoirs. Chinese Journal of Chemical Engineering. 2019(09): 2062-2073 .  必应学术

必应学术

35. Yan-long Li,Neng-you Wu,Fu-long Ning,Gao-wei Hu,Chang-ling Liu,Chang-yin Dong,Jing-an Lu. A sand-production control system for gas production from clayey silt hydrate reservoirs. China Geology. 2019(02): 121-132 .  必应学术

必应学术

36. Yan-long Li,Yi-zhao Wan,Qiang Chen,Jia-xin Sun,Neng-you Wu,Gao-wei Hu,Fu-long Ning,Pei-xiao Mao. Large borehole with multi-lateral branches: A novel solution for exploitation of clayey silt hydrate. China Geology. 2019(03): 333-341 .  必应学术

必应学术

37. 李晨安,李承峰,刘昌岭,邢兰昌,李彦龙,孟庆国. X-CT法研究砂岩中甲烷水合物动态分布规律. 核电子学与探测技术. 2018(02): 266-270 .  百度学术

百度学术

38. 邢兰昌,祁雨,朱泰,陈琳,刘昌岭,孟庆国,刘乐乐. 含甲烷水合物沉积物电–声响应特性联合探测:装置开发与实验研究. 新能源进展. 2018(02): 119-129 .  百度学术

百度学术

39. 张炜,邵明娟,姜重昕,田黔宁. 世界天然气水合物钻探历程与试采进展. 海洋地质与第四纪地质. 2018(05): 1-13 .  本站查看

本站查看

40. 左汝强,李艺. 日本南海海槽天然气水合物取样调查与成功试采. 探矿工程(岩土钻掘工程). 2017(12): 1-20 .  百度学术

百度学术

其他类型引用(33)

下载:

下载: