Technological research progress on CO2-CH4 replacement for hydrate exploitation and enhancement

-

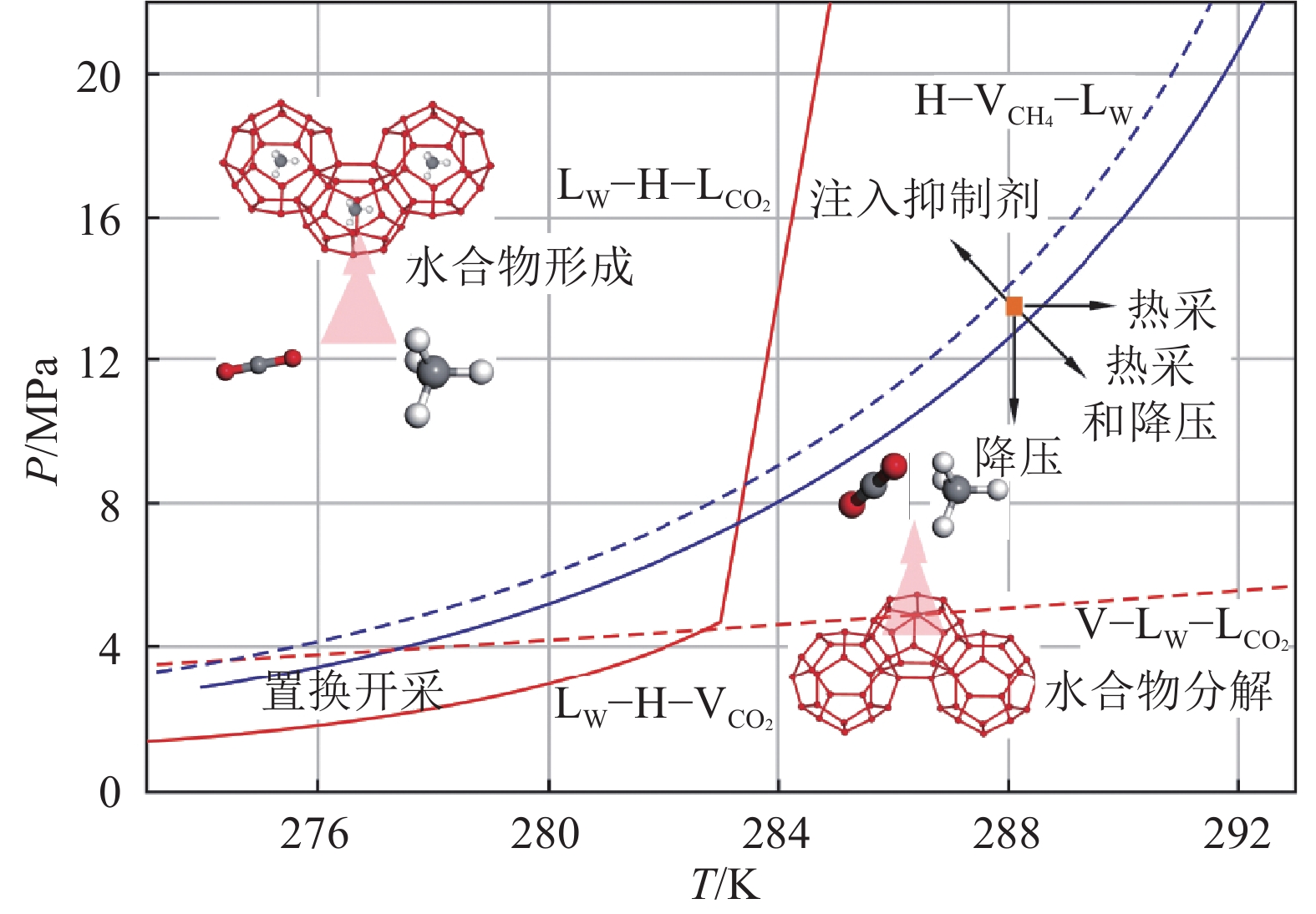

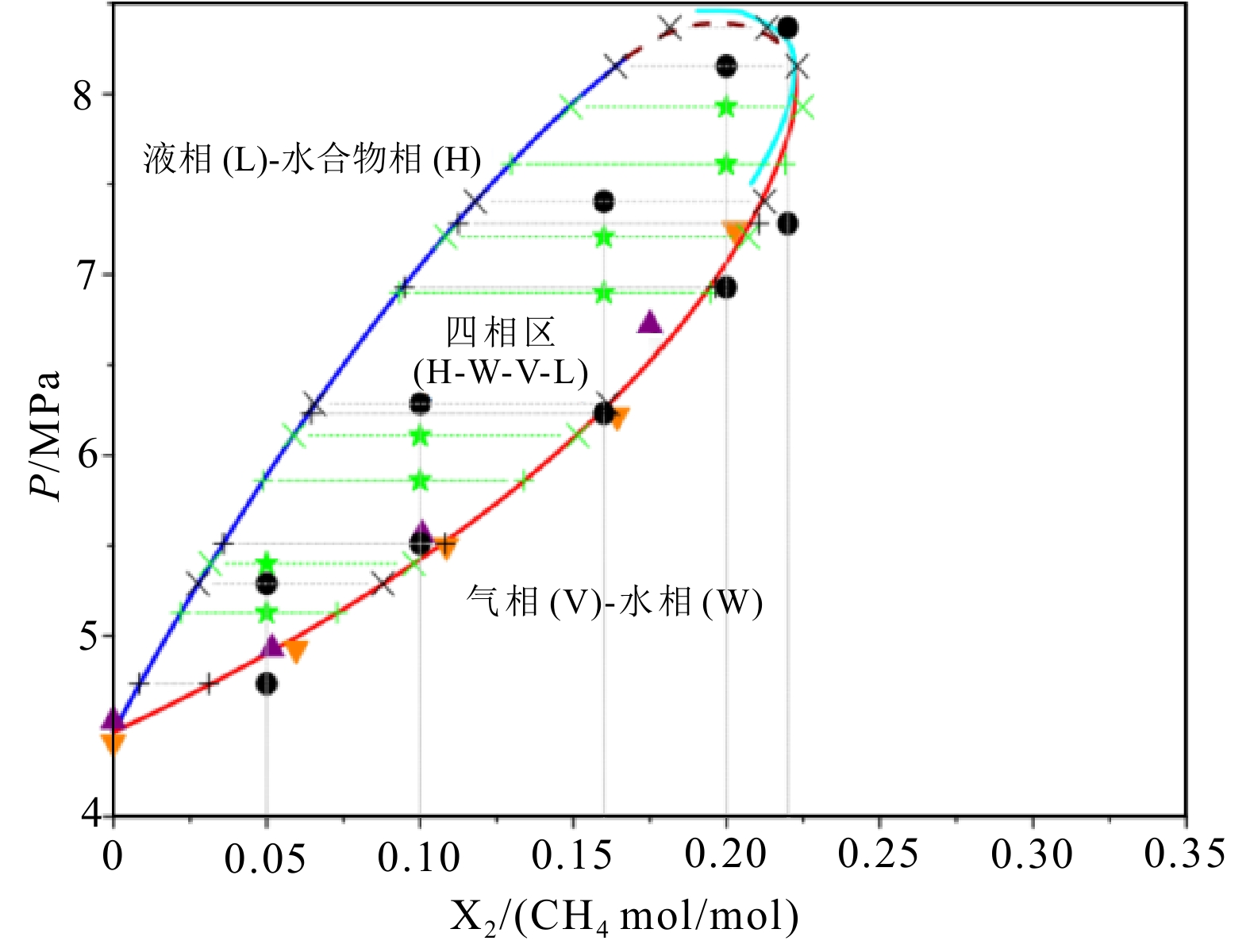

摘要: 天然气水合物具有资源储量大、分布范围广等特点,是一种潜力巨大的替代能源,经济、高效、安全地开发天然气水合物是目前研究的热点。CO2-CH4置换水合物开采法既可以置换出水合物储层中的甲烷,同时还将CO2封存其中以保持地层稳定,受到了广泛的关注。本文从CO2-CH4置换的可行性、实验模拟与数值模拟的角度综述了近些年CO2-CH4置换水合物开采法的最新研究进展,并针对置换过程效率低、速度慢等缺点,探讨了改变CO2注入相态、CO2协同小分子气体以及CO2置换联合开采法等强化置换技术,指出了不同强化方法的技术壁垒及应用局限,展望了CO2-CH4置换水合物开采技术的研究方向和发展前景。Abstract: Considering the huge reserve and wide distribution in nature, natural gas hydrates have a great potential to become an alternative energy resource in future. How to economically and safely recovery natural gas from hydrate reservoirs is the focus of current researches. The method by using carbon dioxide (CO2) to replace methane (CH4) within natural gas hydrates has drawn enormous interests due to its two-fold bonus: CH4 recovery for energy and CO2 sequestration for safety. The latest experimental and numerical research in technology on CO2-CH4 replacement for hydrate exploitation, and the feasibility as well as its challenges were summarized. For the challenges to the low efficiency and slow rate in the replacement process, various methods and technologies to enhance the replacement processes were analyzed on examples of the usage of different phase CO2, cooperation with small-molecule gas, and combination with other exploitation methods. Finally, technical barriers and application limitations of different enhancement technologies were pointed out, and the research direction and development prospect of CO2-CH4 replacement for hydrate exploitation were prospected.

-

第四纪以来的新构造运动是造成海洋地震频发的主要因素之一,海洋地震有时还会引发海啸,会对沿岸地区造成非常严重的损害。中国拥有近2万千米的海岸线,沿海地区人口稠密,分布着多个大、中型城市和众多的城镇,是中国经济较发达的地区。有关资料表明,中国有史以来已发生5级以上地震4000多次,其中近半强震分布于中国沿海与近海地区[1]。研究表明,这些强震的发生,与中国近海分布着多条区域性深大断裂和活动断裂(图1)密切相关[2-3]。因此,研究中国近海的新构造运动特征和规律,一方面为沿海地区的国民经济建设与工程建设提供技术支撑,同时,为地质灾害预测与防震减灾提供科学依据。

![]() F1. 郯庐断裂带,F2. 滨海断裂带,F3. 五莲-青岛-荣成断裂,F4. 嘉山-响水-千里岩断裂,F5. 淄博-五莲-日照断裂,F6. 黄海中央断裂带,F7. 南黄海西缘断裂带,F8. 苏州-湖州断裂,F9. 江绍断裂,F10. 苏北滨海断裂。Figure 1. Schematic diagram of the distribution of regional deep fracture and active faults in offshore China[2-3]F1. Tanlu Fault Zone, F2. Littoral Fault Zone, F3. Wulian-Qingdao-Rongcheng Fault, F4. Jiashan-Xiangshui-Qianliyan Fault, F5. Zibo-Wulian-Rizhao Fault, F6. South Yellow Sea Central Fault Zone, F7. South Yellow Sea West Marginal Fault Zone, F8. Suzhou-Huzhou Fault, F9. Jiangshao Fault, F10. Subei Littoral Fault.

F1. 郯庐断裂带,F2. 滨海断裂带,F3. 五莲-青岛-荣成断裂,F4. 嘉山-响水-千里岩断裂,F5. 淄博-五莲-日照断裂,F6. 黄海中央断裂带,F7. 南黄海西缘断裂带,F8. 苏州-湖州断裂,F9. 江绍断裂,F10. 苏北滨海断裂。Figure 1. Schematic diagram of the distribution of regional deep fracture and active faults in offshore China[2-3]F1. Tanlu Fault Zone, F2. Littoral Fault Zone, F3. Wulian-Qingdao-Rongcheng Fault, F4. Jiashan-Xiangshui-Qianliyan Fault, F5. Zibo-Wulian-Rizhao Fault, F6. South Yellow Sea Central Fault Zone, F7. South Yellow Sea West Marginal Fault Zone, F8. Suzhou-Huzhou Fault, F9. Jiangshao Fault, F10. Subei Littoral Fault.目前,海域新构造运动的调查与研究已成为海洋地质调查研究的重点之一。活动断裂是新构造运动作用中的主要构造表现形式[4],它造成地层层位在空间上不同程度的错断。因此,基于地震反射波的勘探方法是经济、高效和适宜的勘探方法,目前常用的有浅地层剖面仪[5-6]、单道地震[7]、多道地震[8]和海底地震仪(OBS:Ocean Bottom Seismometer)[9] 探测等地震勘探方法。应用这些方法,获得了中国近海深、浅构造耦合关系和活动断裂的展布等一系列成果,为研究海域的新构造运动机理和地震远期预测奠定了良好的基础。本文在收集大量文献的基础上,总结了不同地震勘探方法的特点及在中国近海活动断裂探测中的应用实例,提出了下一步工作的建议。

1. 海洋地震勘探方法特点

1.1 浅部地层高分辨率地震探测方法

海底浅部地层高分辨率地震探测方法一般有浅地层剖面仪、单道地震、高分辨率多道地震。这些方法均是以地震波的反射理论为基础,采用在海水中人工激发地震波,压力型地震检波器接收地震反射信号的方式进行。其中,浅地层剖面仪、单道地震采用的是自激自收(零偏移距)的工作方式,得到的是垂直入射/反射的单道地震反射记录。浅地层剖面仪与单道地震的区别是震源的能量不同,其探测的分辨率和深度存在差异。

1.1.1 浅地层剖面仪探测

浅地层剖面探测是一种基于地震反射波原理,利用浅地层剖面仪(Sub-bottom Profiler System)采用连续走航的方式,探测海底之下浅部地层结构和构造的地震勘探方法[10-12]。浅地层剖面探测的工作方式是,通过电火花等不同类型的换能器震源向海底发射不同频率(频带一般为100~10 kHz)的声波脉冲,该声波在海水和沉积层传播过程中遇到声阻抗界面,被反射返回到压电检波器并转换为数字信号后传送到记录系统中记录下来,在进行滤波处理后输出为能够反映地层声学特征的记录剖面。浅地层剖面仪探测激发地震波震源能量小、频带宽(几十赫兹到几千赫兹)、主频高(几百赫兹到上千赫兹),探测深度在100 m左右,对地层的分辨力为20~50 cm。因此,它能够反映细微的地层物性的变化和微小幅度的构造变化(图2),是探测近海底断裂的有力工具[13]。该方法的缺点是探测深度太小,不能识别断裂向深部的延伸情况。

1.1.2 单道地震探测

单道地震基本原理是利用机械方法引起海底以下中、浅部地层震动,利用专业仪器按照一定的观测方式,记录震源震动后的中、浅部地层中各反射点原始振动信息,再经过一定数据处理得到成像剖面,最后推断解释海底中浅部地层结构和构造特征[14]。

单道地震采集系统主要由控制与记录系统(工作站)、震源、电缆接收系统及导航定位系统组成。震源主要为大功率、高频电火花震源和小容量相干气枪震源(如GI枪);电缆接收主要采用48个等间距排列的水听器组成的单道接收单元。常规的单道地震采集系统采用1个激发震源、1个单元接收水听器的“一发一收”模式,它具有探测深度较大的优点,但由于水听器的排列间距较大,其探测分辨率较低,对地层的分辨能力在5 m左右。最新发展的“一发双收”双通道采集模式,即1个震源激发地震波,2条接收水听器电缆同时接收反射波信号(其中一条为常规接收水听器电缆,另一条为小间距的20个水听器组成的接收单元)。由于小间距水听器接收单元对高频地震波的组合压制效应弱,对浅部地层分辨率较高,但对干扰波的压制能力较差,对埋藏深度较大的地层探测能力不足。因此,“一发双收”的双通道采集模式,可以同步获得2道地震反射记录,达到对浅部地层高分辨率探测和大深度探测的有机结合[15]。

由于采用了气枪和大功率电火花震源,激发的地震波主频率一般为200~500 Hz,较浅地层剖面探测的震源主频有较大的降低,但探测深度得到了提高,一般可探测深度在1000 m以内的地层,对浅部地层的探测分辨率为0.5~3 m,对深部地层的分辨率为5~6 m。因此,单道地震探测可以研究浅部断裂向深部的延伸及与深大断裂的耦合情况,但对断距小于分辨率的断裂难以识别。

1.1.3 高分辨率短排列多道地震勘探

虽然浅地层剖面、单道地震探测具有拖曳电缆短、施工快捷高效、数据处理简便、分辨率高等优点,但由于其为单道接收的垂直入射/反射地震信号,缺失偏移距信息而无法进行速度分析,也不能进行基于多次叠加的信噪比提升和成像处理,多次波压制和噪音剔除处理难度大,数据的信噪比低等问题突出。另外,新构造研究的目标之一是查明是否存在活动的构造断裂,也就是要寻找构造断层,并非第四纪沉积断层或海底滑坡,这就要求地震探测不仅对浅部地层有较高的分辨率,而且要对沉积基底(即第四系—新近系的底界)清晰成像[16]。中国近海有较大部分区域的沉积基底埋藏深度达1500 m以上,勘探深度更大并且对沉积基底成像更精确的高分辨率多道地震调查方法,成为沉积基底埋藏深度大的区域活动断裂调查的主要勘探方法。

早期的高分辨率多道地震探测是在油气地震勘探基础上发展、改造而成的,一般采用25 m或12.5 m道间距的24道/48道地震电缆,为了提高勘探分辨率,电缆的沉放深度较小,一般小于3 m,同时采用小容量、浅沉放的气枪震源,勘探深度在2 000 m左右,满足了对沉积基底埋藏深度大的地区活动断裂调查的需求[16-17],但由于常规海洋地震勘探电缆的道间距大,地震勘探的横向分辨率较低。

为了在保持勘探深度的同时提高探测分辨率,自然资源部第一海洋研究所等在“863”计划的支持下,研制了由震源激发系统、地震信号接收系统和导航定位系统组成的近海高分辨率多道地震拖缆勘探系统。其中,震源系统配置大能量、高频电火花震源或GI型气枪震源;地震信号接收系统配备3.25 m道间距的24道等浮接收电缆(可扩充到48道或96道),每道由两个或多个水听器组成,多个检波器组合主要是利用干扰波与有效波特征及差异与视速度差异在资料采集阶段压制某些干扰波[18],道间距的大幅度缩小带来了更高的横向探测分辨率,有力地保障了勘探精度。采集的地震资料的成像处理结果表明,该系统能够有效探测到基岩的起伏,且疏松沉积层的分辨率高(图3)。

海上采集的高分辨率多道地震资料经过精细成像处理后才能用于构造与地层解释。因此,地震资料成像处理是高分辨率多道地震勘探的重要环节之一,也是提高资料分辨率和信噪比的有效途径[19]。主要采用SRME浅水多次波压制技术[20]、线性干扰压制的TAUP变换方法[21]、压制虚反射的抛物线Radon变换方法[22]等噪音压制技术方法。由于高分辨率短排列多道地震的原始资料特点,其成像处理的技术难度较大,主要是这种地震采集方式的接收排列短(通常小于500 m),提供速度分析所需的旅行时差信息较少,造成精细速度分析精度差,采用基于相似性原理的排列长度放大技术,有效地解决了排列长度较短引起的速度谱能量团不聚焦、影响速度分析灵敏度的问题[23]。

中国浅海区以油气勘探为目标采集了大量的长排列高分辨率地震资料。在渤海海域将高分辨率地震资料中的近偏移距地震道数据,在采取常规处理方法的同时,采用地震相分析、波阻抗反演、井震标定、属性分析等特殊处理技术,提高了成像处理剖面分辨率,预测了活动断裂分布,形成了一套利用高分辨率地震资料预测海底及浅层地质灾害的技术方法[24],为活动断裂的地震探测提供了新的技术思路。

1.2 长排列多道地震探测

海洋拖缆多道地震勘探是海洋油气资源和区域地质调查的重要手段之一,目前已形成了较为成熟的资料采集、处理和解释的技术方法。海洋拖缆多道地震勘探以专业的地震调查船为载体,将仪器设备安装在地震船上,使用海上专用的压电检波器和电缆,激发系统多使用气枪阵列,由地震船牵引拖缆按测线方向行进,形成边行进、边激发、边接收的工作方式。现今的海洋多道地震勘探具有以下特点[11]:(1)震源容量大、能量强,多采用多支容量不等的气枪组成的大容量气枪阵列(总容量为3000~6000 in3甚至更高)作为激发地震波震源,结合立体阵列延迟激发等新技术方法[8,25-26],其低频能量强,穿透能力可达10000 m以上;(2)电缆长、接收道数多,一般以12.5 m的道间距,记录地震波反射的道数在480道以上,电缆长度达6000 m以上;(3)采用多次覆盖的采集方式,覆盖次数达100次以上,成像剖面信噪比较高;(4)探测深度大,可获得埋藏深度10000 m左右沉积盆地基底的有效反射;(5)分辨率较低,由于大容量气枪阵列震源激发特性的限制,激发地震波的主频一般只有20~30 Hz,有效频带为6~80 Hz,对勘探目标分辨能力较低,属于中-低频地震勘探范畴。

多道拖缆地震的勘探深度大,对探测深达盆地基底的大断裂非常有利,在对成像剖面进行常规解释的同时,结合高分辨率处理[27]、地震相分析[28]、反演[29-30]与属性分析[31-34]等技术方法,可以弥补分辨率的不足,在识别大断裂的同时预测浅部的活动断裂,进而分析大断裂与活动断裂的耦合关系,研究新构造运动机理。

1.3 地壳结构的地震探测方法

研究认为,现今板块边界和运动学图像的建立是新构造运动最合适的标志[35],新构造研究的时间尺度较长,重点是百万年至十万年尺度的地质构造过程,更注重探索“过去”,涉及构造形迹(断裂与褶皱)及其演化等领域。OBS深部地学探测能够获得宏观地壳速度结构,是研究板块边界、识别深大断裂的重要手段[9,36]。

OBS深地震探测是一种将检波器直接放置在海底的地震观测系统,分为主动源(人工源)和被动源(天然源)两种探测方式。主动源探测首先沿测线按一定的间距(一般为5~30 km)将OBS投放到海底形成接收台站,然后沿测线用大容量气枪阵列震源等间距地激发地震波,OBS台站接收激发的所有地震波,形成共检波点(共接收点)记录,它记录了从炮检距零米(垂直入射/反射波)到上百千米(甚至几百千米)的地震信号,所以OBS台站记录既包含了反射波信号(包括近炮检距和远炮检距的广角反射信号),也接收到了来自于地壳内部主要地层界面的折射波信号;对OBS台站记录的原始地震数据采用数据分析、震相辨认、射线追踪和走时模拟等处理方法,可以获得测线下方地壳结构的二维纵波、横波速度模型[37-38]。

被动源OBS探测使用宽频带OBS,如国产宽频带、7通道(I-7C型)OBS,采用单球一体化结构,7通道的采集(3通道宽带地震计(频带宽带30 s~40 Hz)、3通道高频检波器、1通道水听器),同时具备了接收人工震源信号和低频天然地震信号的能力[9]。通过将宽频带OBS布设在靠近板块边界或深大断裂附近及观测海域,记录有关地震活动性的更详细的信息,特别是小地震的信息,根据记录的大量与构造运动有关的微震数据,通过采用层析成像等处理方法,勾画出地壳-上地慢的速度结构[39-41]。

OBS放置在海底,直接接收在海底地层中传播的地震信号,可以同时记录两个水平方向上传播的地震波(横波)、一个垂直方向地震波(纵波)和一个水听器数据,在进行纵波探测的同时,还可以进行横波探测,得到纵波、横波速度结构和泊松比等地层物性参数,为研究地层岩性、识别火成岩等提供物性依据[36,42-45],而火成岩的分布是活动构造研究的内容之一。

因此,在海洋地球物理调查和研究中,OBS探测既可以用于对海洋人工地震剖面的探测,也可以用于对天然地震的观测,其探测和观测结果可以用于研究海洋地壳和地幔的速度结构及板块俯冲带、海沟、海槽演化的动力学特征,也可以用于研究天然地震的形成机理以及活动性并进行地震预报等[46]。

OBS探测的特点是深度大,能够得到反映地壳宏观结构的速度特征(图4),但其分辨率较低,只能反映地壳范围内的宏观速度结构。

2. 应用实例

目前,地震勘探技术在中国近海新构造运动研究中取得了大量的成果。基本查明了与活动断裂有关的区域性深大断裂(图1)和第四纪仍在活动的浅层断裂。通过使用二维及三维高分辨率多道地震剖面,结合层序地层学分析等解释方法,认识到渤海海域在郯庐断裂带形成的走滑拉张环境下,浅层断层向下逐渐归拢至深大断裂,断至海底后形成所谓的“通天”断层[24],在更新世末又发育一次区域挤压产生的褶皱,多道地震剖面上也可见到界面上下明显的角度不整合和大量密集的张扭性断层[47],造成渤海盆地浅层断裂十分发育,主体构造线呈NE、NNE或近EW向展布,这些也得到高分辨率单道地震测网成果的支持[48];营口-潍坊断裂的晚期活动对渤海浅层断裂系统的发育具有重要的控制作用,新近纪基底的断裂数量大约是古近纪基底断裂的3~4倍,而第四纪基底又是新近纪基底断裂数量的2倍[49]。通过对二维多道地震剖面的目标解释,也得到了南黄海盆地西北部与深大断裂相关的第四纪活动断裂的分布,揭示了NW-SE挤压型活动断裂的存在,并伴随着“背驮式”扩展型构造,说明其还在持续活动[50]。

如前所述,浅地层剖面探测、单道地震和高分辨率多道地震方法是研究活动断裂的主要工具,在中国近海活动断裂探测中发挥了重要作用。利用浅地层剖面仪对郯庐断裂带莱州湾段进行了活动断裂探测,发现第四纪晚期以来郯庐断裂带主干断裂仍在活动,并继承了新近纪以来的主要构造活动特点,仍是这一区域的主导性构造[51]。在渤海采用水枪震源单道地震方法获得了垂向穿透深度约300~500 m、垂向分辨率约2~3 m的地震剖面,同时采用电火花震源单道地震方法,还获得了垂向穿透50~80 m、垂向分辨率约0.5~1 m的地震剖面,在此基础上研究了渤海海域郯庐断裂段晚更新世以来的分布和活动特征,认为莱州湾和渤中海域郯庐断裂的最新活动时间为全新世早期,形成了褶皱和倾向相同或相反的更次一级张性断裂,辽东湾内最新活动时间为晚更新世晚期,形成了倾向相同或相反的更次一级断裂,这些和地震活动有明显的对应关系[6,52]。另外,浅地层剖面探测揭示,郯庐断裂带的次级断裂是1969年的渤海7.4级地震的发震断裂,其最新活动时间为全新世中晚期,根据地质时代以及断层的垂向位移量计算推断,晚更新世—全新世具有活动强度增加的趋势[6]。

随着渤海海峡跨海通道设想的提出,该区域的新构造运动特征成为研究的热点。研究者采用了常规多道地震和高分辨率单道地震的探测方法,探测了渤海海峡的活动断裂等新构造运动特征[52],认识到渤海海峡活动断裂发育,主要发育NE、NW、SN和EW向四组断裂系统,NE向断裂和NW向断裂为占绝对优势的断裂系统(图5)。其中,NNE向郯庐断裂是渤海海域中最重要的断裂带,最新活动时代为全新世早期,晚更新世—全新世各个时段的垂向活动速率超过0.06 mm/a,近20 kaBP的垂向活动速率超过0.08 mm/a[53];张家口-蓬莱-威海NW向断裂晚第四纪以来主要表现为垂向运动,最新活动时代为晚更新世末—全新世,在60 kaBP 和20 kaBP左右活动强烈, 近20 kaBP以来的垂向活动速率超过0.06 mm/a[6];五莲-青岛-海州NEE及近EW向断裂为华北块体与苏胶临津江造山带的分界断裂,该断裂在青岛-荣成段的切割深度较浅,在海域被黄海中央断裂带阻断[54]。

![]() 图 5 渤海海峡调查区断裂分布示意图NW向断裂:1. 碧流河断裂,2. 长兴岛断裂,3. 大连湾断裂,4. 旅顺断裂,5. 老铁山水道断裂,6. 钦岛断裂,7. 桑沟湾断裂,8. 靖海湾断裂,9. 浪暖口断裂,10. 老龙头断裂,11. 田横岛断裂,12. 鳌山湾断裂;NE及NEE向断裂:13. 千里岩西部断裂,14. 千里岩东部断裂,15. 沙子口断裂,16. 荣成隆起南断裂,17. 荣成隆起北部断裂,18. 四十里湾断裂,19. 套子湾断裂,20. 蓬莱湾断裂,21. 庙岛陆坡断裂,22. 庙岛集束断裂,23. 渤中底劈断裂,24. 辽东湾中央东断裂,25. 辽东湾中央断裂,26. 辽东湾中央西断裂。Figure 5. Schematic diagram of fault distribution in the survey area of Bohai StraitNW Fault:1. Biliuhe fault, 2. Changxing Island fault, 3. Dalian Bay fault, 4. Lushun fault, 5. Laotieshan waterway fault, 6. Qin Island fault, 7. Sangou Bay fault, 8. Jinghai Bay fault, 9. Langnuankou fault, 10. Laolongtou fault, 11. Tianheng Island fault, 12. Aoshan Bay fault; NE and NEE fracture: 13. Qianliyan western fault, 14. Qianliyan eastern fault, 15. Shazikou fault, 16. Rongcheng uplift south fault, 17. Rongcheng uplift northern fault, 18. Sishili Bay fault, 19. Taozi Bay fault, 20. Penglai Bay fault, 21. Miaodao continental slope fault, 22. Miaodao cluster fault, 23. Bozhong bottom split fault, 24. Liaodong Bay Central East Fault, 25. Liaodong Bay Central Fault, 26. Liaodong Bay Central West Fault.

图 5 渤海海峡调查区断裂分布示意图NW向断裂:1. 碧流河断裂,2. 长兴岛断裂,3. 大连湾断裂,4. 旅顺断裂,5. 老铁山水道断裂,6. 钦岛断裂,7. 桑沟湾断裂,8. 靖海湾断裂,9. 浪暖口断裂,10. 老龙头断裂,11. 田横岛断裂,12. 鳌山湾断裂;NE及NEE向断裂:13. 千里岩西部断裂,14. 千里岩东部断裂,15. 沙子口断裂,16. 荣成隆起南断裂,17. 荣成隆起北部断裂,18. 四十里湾断裂,19. 套子湾断裂,20. 蓬莱湾断裂,21. 庙岛陆坡断裂,22. 庙岛集束断裂,23. 渤中底劈断裂,24. 辽东湾中央东断裂,25. 辽东湾中央断裂,26. 辽东湾中央西断裂。Figure 5. Schematic diagram of fault distribution in the survey area of Bohai StraitNW Fault:1. Biliuhe fault, 2. Changxing Island fault, 3. Dalian Bay fault, 4. Lushun fault, 5. Laotieshan waterway fault, 6. Qin Island fault, 7. Sangou Bay fault, 8. Jinghai Bay fault, 9. Langnuankou fault, 10. Laolongtou fault, 11. Tianheng Island fault, 12. Aoshan Bay fault; NE and NEE fracture: 13. Qianliyan western fault, 14. Qianliyan eastern fault, 15. Shazikou fault, 16. Rongcheng uplift south fault, 17. Rongcheng uplift northern fault, 18. Sishili Bay fault, 19. Taozi Bay fault, 20. Penglai Bay fault, 21. Miaodao continental slope fault, 22. Miaodao cluster fault, 23. Bozhong bottom split fault, 24. Liaodong Bay Central East Fault, 25. Liaodong Bay Central Fault, 26. Liaodong Bay Central West Fault.南黄海北部海域的千里岩断裂是一条区域性深大断裂,也是南黄海北部盆地与千里岩隆起的分界断裂,其活动性备受关注。浅地层探测剖面、单道地震显示千里岩断裂在晚更新世仍在活动[55],多道地震剖面显示其主要受深大断裂控制(图6),活动段长度大于100 km,具有发生约6.5级地震的可能性,在地震预报和地震危险性分析中值得进一步研究。高分辨率单道地震剖面显示千里岩附近海域是千里岩隆起区构造较活跃地区,第四纪构造变形较显著,形成较多的褶皱和断层构造,千里岩断裂和嘉山-响水断裂带在第四纪以来均有活动,其中千里岩断裂活动时代较新,属于晚更新世活动断层[56]。覆盖整个千里岩隆起带的高分辨率多道地震显示千里岩隆起带发育3条NE走向的第四纪活动断裂,最新活动时间为早更新世—晚更新世[57]。

东海陆架盆地是中国东部海域典型的中、新生代断坳二元盆地,上新世晚期以来的新构造运动活跃,主要表现形式有断裂、褶皱、地震及岩浆的侵入与喷发,高分辨率多道地震和单道地震揭示了多条活动断裂(图7)和两个岩浆活动密集区,截止时间为中新世—全新世,整体西带沿东海陆架西部至浙、闽、粤近海呈NE-NNE向、近EW向及NW-NNW向展布[58-59]。东海陆架区新构造运动呈现从中新世到第四纪沉降中心自西向东迁移,活动断裂新构造期的活动性自西向东逐渐变新,岩浆活动自西向东逐渐变新、侵入活动逐渐减弱、喷发活动逐渐增强[59],表明板块俯冲和冲绳海槽的扩张作用是造成东海陆架区新构造运动活跃的主要因素。

华南地区的近海海域主要为南海东北部,地处欧亚板块与菲律宾海板块的交汇区,新构造运动活跃[60],沿福建、广东海岸30~50 m海水等深线分布着一条绵延上千千米、活动强度高的NEE走向断裂带——滨海断裂带,决定了南海北部大陆边缘地震的分布和强度,在该断裂带历史上发生了多次7级以上的强震[61]。因此,对滨海断裂带的调查与研究备受关注。研究者采用OBS深部地学探测的方法调查研究了断裂带的地壳结构特征与震源构造,基本查清了滨海断裂带的地质结构,发现滨海断裂带断至莫霍面,为华南亚板块与南海亚板块的分界断裂,是南海东北部的重要控震和发震构造,在上地壳下部普遍存在一层速度为5.5~5.9 km/s、厚度为2.5~4.0 km的低速地层,滨海断裂带与上地壳下部的低速地层的构造交接部位形成南海东北部的重要应力集中带和应变能积聚带,是地震孕育、发生的深部动力学条件[61-63]。

3. 展望

中国近海新构造运动的地震探测取得了丰富的成果,主要集中于经济发达、地震活动强烈的近海海域,研究主要借鉴陆域活动构造的研究方法,成果多集中于活动性及其分布规律方面,存在最新活动时间的厘定不精准、定量参数的研究程度较低,浅层活动构造成因机制的研究薄弱,海域活动构造自身因素的危险性定量评价研究欠缺等问题[64]。针对这些问题,地震勘探技术未来将得到较大的发展,应用广度和深度都将进一步拓展。

(1)多方法组合系统调查与研究是新构造运动研究的有效途径

如前所述,不同的探测方法具有各自的优势和缺陷(表1),单一的方法难以达到准确描述构造特征的目的。因此,聚焦浅层活动构造成因机制的研究目标,未来将联合采用浅地层剖面、单道地震和高分辨率多道地震,大容量气枪阵列震源、长排列多道地震及OBS深部探测的技术方法,综合利用不同探测方式的分辨率和探测深度优势,系统地调查研究地壳的浅、中、深部地质结构,第四纪沉积环境的变迁,活动断裂最新活动时间、强度及其与深大断裂的耦合关系,为研究活动构造成因机制提供系统而全面的地震勘探资料。

表 1 主要地震勘探方法对比Table 1. Comparison of main seismic exploration methods探测方法 分辨率 勘探深度 工作方式 主要用途 浅地层剖面 20~50 cm 100 m左右 电火花震源激发,拖曳式单道接收 用于全新世地质特征和活动断裂探查 单道地震 2~5 m(和震源的激发能量有关) 500~1000 m(和震源的激发能量有关) 电火花震源或小容量气枪激发,拖曳式单道接收 用于第四纪地质特征和活动断裂探查与成岩基底相关的活动断裂探查 高分辨率多道地震 1~3 m 1000~1500 m 大能量电火花或相干气枪激发,小间距多道接收 用于新生代地质特征和活动断裂探查与成岩基底相关的活动断裂探查 长排列多道地震 几十米到几百米 几千米到上万米 大能量气枪阵列震源激发,长排列多道接收,道数可达几百道 用于区域地质和探查盆地基底 海底地震仪(OBS) 分辨率低,只反映地层宏观速度结构 可达莫霍面 大能量气枪枪阵激发,单点独立式接收 用于探查地壳构造、深部断裂和中到深大断裂 (2)提高地震勘探的精度是研究新构造运动的有效途径

新构造运动最新活动时间的精准厘定,需要在地震剖面上准确地标定活动断裂顶部的终止层位,要求地震剖面的分辨率达到厘米级甚至更高,目前分辨率最高的浅地层剖面探测分辨能力在50 cm左右,还不能完全满足活动时间的精准厘定的要求,未来还要继续开发更高分辨率、更高导航精度的浅部地震探测技术,以得到更高勘探精度的地震资料,满足对活动断裂和地层岩性、沉积等精确厘定的需要。

(3)横波地震勘探技术是研究新构造的有益探索

众所周知,地层的横波速度低于纵波速度,陆地的勘探实践证明,浅部疏松地层的横波速度大致相当于纵波速度的一半左右[65]。因此,在相同的地震波频带范围内,横波地震勘探分辨率高于纵波地震勘探,是提高勘探分辨率的一个新途径。但是,在海洋地震勘探中,由于横波不能在海中传播,以海水为接收介质的地震勘探方法(如拖缆多道地震、单道地震和浅地层剖面探测)难以得到横波信号。因此,在海域里实施高分辨率横波地震勘探,还面临震源和检波器等设备的瓶颈问题,海洋高分辨率横波地震探测装备的研发和勘探技术的攻关,将成为未来努力的方向之一。在目前已有的装备条件下,采用OBC[66]、OBN[67]和OBS等海底接收地震信号的勘探方法,接收地震转换波达到横波勘探的目的。另外,利用最新发展的海底可控震源激发地震波技术[68],通过在海底激发地震波和提高振动器的主频率,实现对激发地震波频带的有效控制,提高转换横波的分辨率,以提高达到有效利用横波优势的目的。

-

表 1 不同相态CO2的强化置换效果

Table 1 Enhanced displacement effect with CO2 in different states

CO2相态 检测手段 介质体系 温度/K 压力/MPa 甲烷回收效率 文献来源 液 GC 冰粒/纯水 263/275 9 14%/40.3% Lee等[56] 液 Raman 纯水 273.2 3.6/5.4/6 37.6%/27%/29% Ota等[62-63] 液 GC 纯水 283.5 4.5/5.0 20.60%/18.11% 张凤琦等[64] 液 GC 石英砂+水 282.15 6~8 13%~45.4% Zhang等[42] 液 GC 石英砂+盐水 275.2 4.19~4.21 26%~33% Yuan等[33] 液 GC 石英砂+盐水 280.2 4.2 35% Yuan等[33] 液 GC 石英砂+ SDS溶液 281.2 5 18.6% Zhou等[65] 液 GC 石英砂+盐水 273.2 4 26.4% Wang等[66] 液 Raman+SEM 纯水 277 6 11.4% Falenty等[67] 液 MRI 砂岩+盐水 273.2 8.3 59% Kvamme等[68] 乳液 GC 石英砂+ SDS溶液 281.2 5 17%/27.1% Zhou等[65,69] 乳液 GC 石英砂+水 281 5 27.1% 周锡堂等[70] 超临界 GC 石英砂+冰颗粒/盐水 275.2 7.5 37.5% Deusner等[71] 超临界 GC 石英砂+冰颗粒/盐水 275.2/281.2/283.2 13 3.4%/40.7%/10.7% Deusner等[71] 注:GC:气相色谱技术,Raman:拉曼光谱技术,SEM:扫描电子显微镜技术,MRI:核磁共振成像技术。 表 2 不同CO2/N2注气比的强化置换效果

Table 2 Enhanced displacement effect at different CO2/N2 injection ratios

气体成分(CO2/N2) 检测手段 介质体系 温度/K 压力/MPa 甲烷回收效率 文献来源 10%CO2+90%N2 NMR+DSC 多孔硅胶+水 274 11.54/14.59/18.59 77%/80%/79% Lee等[74] 10%CO2+90%N2 GC 纯水+SDS溶液 298.15 9.05 41% Pandey等[88] 14.6%CO2+85.4%N2 GC 硅砂+水 273.3 4.2 53.3% Yang等[89] 19%CO2+81%N2 GC 石英砂+冰粒 274.15 15.8 6.1% 王曦等[90] 20%CO2+80%N2 Raman+NMR 粉末冰颗粒 274.15 12 85% Park等[91] 20%CO2+80%N2 SEM 黏土+水 273.15 15 85% Koh等[92] 20%CO2+80%N2 NMR+GC 多孔硅胶+水 273 10 42% Cha等[93] 20%CO2+80%N2 GC 玻璃珠+水 275.15 9.8 49.2% Koh等[94] 20%CO2+80%N2 GC 玻璃珠+水 274 9.5 39.3% Youn等[95] 22%CO2+78%N2 GC 石英砂+盐水 273.2 5.0 36.9 Liu等[87] 23%CO2+77%N2 Raman+GC 石英砂+水 281 10 90% Schicks等[35] 25%CO2+75%N2 GC 砂土+水 274.2 10 25% Pan等[96] 25%CO2+75%N2 GC 高岭石+水 274.2 10 24.5% 潘栋彬等[97] 25%CO2+75%N2 GC 伊利石+水 274.2 10 25% 潘栋彬等[97] 25%CO2+75%N2 GC 蒙脱石+水 274.2 10 18.2% 潘栋彬等[97] 28%CO2+72%N2 GC+CCD 纯水+ SDS溶液 284.2 9.02 13.2% Niu等[98] 40%CO2+60%N2 NMR+GC 多孔硅胶+水 274 10 51% Seo等[99] 50%CO2+50%N2 Raman+CCD+GC 纯水 273.9 5/6.67 8.3%/17.7% Zhou等[100] 53%CO2+47%N2 GC 石英砂+冰粒 274.15 2.1/3.4 12.6%/19% 王曦等[90] 53%CO2+47%N2 GC 纯水 279.15 8.01 52.42% Ouyang等[101] 53%CO2+47%N2 GC 石英砂+热水 274.15 14 91.6% 操原[102] 59%CO2+41%N2 GC 石英砂+水 277.15 7 40.8% Yasue等[86] 60%CO2+40%N2 GC 石英砂+水 277.15/280.15 7 30% Masuda等[103] 60%CO2+40%N2 Raman+FTIR+GC 纯水 274 4.5 73.42% Xu等[41] 75%CO2+25%N2 GC 石英砂+冰粒 275.15 3 41.4% Li等[82] 75%CO2+25%N2 GC 石英砂+水 275.65 4.8 68.8% Tupsakhare等[104] 75%CO2+25%N2 Raman+CCD+GC 纯水 274 2.6/3.11/3.5 9.5%/12.6%/17.9% Zhou等[100] 87.6%CO2+12.4%N2 GC 石英砂+水 277.15 8.9 46.32% Mu等[75] 注:DSC:差式扫描量热技术,NMR:核磁共振技术,CCD:影像检测技术,FTIR:红外光谱技术。 表 3 不同热激发方式的强化置换效果

Table 3 Enhanced replacement effects in different thermal excitation methods

热激发方式 介质体系 温度/K 压力/MPa 甲烷回收效率(无热激发) 甲烷回收效率(有热激发) 文献来源 热烟气(CO2/N2) 硅砂+水 273.3 4.2 15.9% 53.3% Yang等[89] 短暂升高温度 玻璃珠+水 273.7 3.69 11.55% 59.16% Zhang等[108] 重复注热+分阶段注热 石英砂+冰粒 271.15 3 28% 82% Stanwix等[109] 间歇式原位加热 纯水 280.15 8 35.64% 64.80% 欧阳潜[110] 间歇式原位加热+脉冲注热 纯水 275.15 4 19.83% 35.50% Ouyang等[101] 脉冲注热 纯水 279.15 8 40% 55% 张育诚[111] 热电偶原位加热 石英砂+水 275.65 3.3 24% 99% Tupsakhare等[112] 热电偶原位加热+注入CO2/N2 石英砂+水 275.65 4.8 50% 68.8% Tupsakhare等[104] 表 4 不同强化方法对置换效率的影响对比

Table 4 Comparison of the effects in different strengthening methods on the replacement efficiency

强化方法类型 突出优势 主要影响因素 注液态CO2 特定成核位置的CO2浓度更高,有利于快速成核 水合物储层粒径 注CO2乳化液 具有更高的反应温度以及更好的传导性和扩散能力 乳化液的含量和种类 注CO2/N2混合气 降低CH4分压,置换出512小笼子中的CH4分子 不同气体比 与热激发法联合 缓解CH4水合物分解引起的局部热损 水合物储层饱和度 与降压法联合 CH4水合物的局部分解为CO2的渗透作用提供了更加丰富的孔隙通道 压降梯度 与注化学剂法联合 使相平衡条件向有利于CH4水合物分解和CO2水合物合成的方向移动 化学剂浓度 -

[1] Sloan E D Jr. Fundamental principles and applications of natural gas hydrates [J]. Nature, 2003, 426(6964): 353-359. doi: 10.1038/nature02135

[2] Sloan E D Jr, Koh C A. Clathrate Hydrates of Natural Gases[M]. Boca Raton: CRC Press, 2007.

[3] Nair V C, Prasad S K, Kumar R, et al. Energy recovery from simulated clayey gas hydrate reservoir using depressurization by constant rate gas release, thermal stimulation and their combinations [J]. Applied Energy, 2018, 225: 755-768. doi: 10.1016/j.apenergy.2018.05.028

[4] Kou X, Wang Y, Li X S, et al. Influence of heat conduction and heat convection on hydrate dissociation by depressurization in a pilot-scale hydrate simulator [J]. Applied Energy, 2019, 251: 113405. doi: 10.1016/j.apenergy.2019.113405

[5] Gambelli A M, Rossi F. Natural gas hydrates: Comparison between two different applications of thermal stimulation for performing CO2 replacement [J]. Energy, 2019, 172: 423-434. doi: 10.1016/j.energy.2019.01.141

[6] Gupta P, Nair V C, Sangwai J S. Polymer-Assisted chemical inhibitor flooding: a novel approach for energy recovery from hydrate-bearing sediments [J]. Industrial & Engineering Chemistry Research, 2021, 60(22): 8043-8055.

[7] Nair V C, Mech D, Gupta P, et al. Polymer flooding in artificial hydrate bearing sediments for methane gas recovery [J]. Energy & Fuels, 2018, 32(6): 6657-6668.

[8] Rossi F, Gambelli A M, Sharma D K, et al. Experiments on methane hydrates formation in seabed deposits and gas recovery adopting carbon dioxide replacement strategies [J]. Applied Thermal Engineering, 2019, 148: 371-381. doi: 10.1016/j.applthermaleng.2018.11.053

[9] Koh D Y, Kang H, Lee J W, et al. Energy-efficient natural gas hydrate production using gas exchange [J]. Applied Energy, 2016, 162: 114-130. doi: 10.1016/j.apenergy.2015.10.082

[10] Fakher S, Elgahawy Y, Abdelaal H. A comprehensive review on gas hydrate reservoirs: Formation and dissociation thermodynamics and rock and fluid properties[C]//International Petroleum Technology Conference. Beijing: International Petroleum Technology Conference, 2019.

[11] 徐行, 罗贤虎, 彭登, 等. 中国首次试采天然气水合物成功[J]. 中国地质, 2017, 44(3):620-621 doi: 10.12029/gc20170323 XU Xing, LUO Xianhu, PENG Deng, et al. First successful trial collection of natural gas hydrate in China [J]. China Geology, 2017, 44(3): 620-621. doi: 10.12029/gc20170323

[12] 叶建良, 秦绪文, 谢文卫, 等. 中国南海天然气水合物第二次试采主要进展[J]. 中国地质, 2020, 47(3):557-568 doi: 10.12029/gc20200301 YE Jianliang, QIN Xuwen, XIE Wenwei, et al. Main progress of the second gas hydrate trial production in the South China Sea [J]. China Geology, 2020, 47(3): 557-568. doi: 10.12029/gc20200301

[13] Komai T, Kawamura Y K T, Yoon J H. Extraction of Gas Hydrates using CO2 sequestration[C]//The Thirteenth International Offshore and Polar Engineering Conference. Honolulu: The International Society of Offshore and Polar Engineers, 2003.

[14] Birkedal K A, Ersland G, Husebo J, et al. Geomechanical stability during CH4 production from hydrates-depressurization or CO2 sequestration with CO2-CH4 exchange[C]//44th U. S. Rock Mechanics Symposium and 5th U. S. -Canada Rock Mechanics Symposium. Salt Lake City: American Rock Mechanics Association, 2010.

[15] 张学民, 李银辉, 张山岭, 等. 多孔介质中CO2-CH4水合物置换过程的强化方法研究进展[J]. 过程工程学报, 2022, 22(4):438-447 doi: 10.12034/j.issn.1009-606X.221122 ZHANG Xuemin, LI Yinhui, ZHANG Shanling, et al. Research progress of enhancement methods of CO2-CH4 hydrate displacement in porous media [J]. The Chinese Journal of Process Engineering, 2022, 22(4): 438-447. doi: 10.12034/j.issn.1009-606X.221122

[16] Ebinuma T. Method for dumping and disposing of carbon dioxide gas and apparatus therefor: US, 5261490[P]. 1993-11-16.

[17] 王敏, 徐刚, 蔡晶, 等. “CH4-CO2”置换法开采天然气水合物[J]. 新能源进展, 2021, 9(1):62-68 WANG Min, XU Gang, CAI Jing, et al. Research progress on the micro-mechanism and efficiency of CH4-CO2 replacement and extraction of CH4 hydrate [J]. Advances in New and Renewable Enengy, 2021, 9(1): 62-68.

[18] Ohgaki K, Takano K, Sangawa H, et al. Methane exploitation by carbon dioxide from gas hydrates-phase equilibria for CO2-CH4 mixed hydrate system [J]. Journal of Chemical Engineering of Japan, 1996, 29(3): 478-483. doi: 10.1252/jcej.29.478

[19] Schoderbek D, Farrell H, Howard J, et al. ConocoPhillips gas hydrate production test[R]. Houston, TX: ConocoPhillips Co. , 2013.

[20] Schoderbek D, Boswell R. Iġnik Sikumi #1, gas hydrate test well, successfully installed on the Alaska North Slope [J]. Fire in the Ice-Methane Hydrate Newsletter, 2011, 11: 1-5.

[21] Ohgaki K, Takano K, Moritoki M. Exploitation of CH4 hydrates under the Nankai Trough in combination with CO2 storage [J]. Kagaku kōgaku ronbunshū, 1994, 20(1): 121-123. doi: 10.1252/kakoronbunshu.20.121

[22] Mu L, Von Solms N. Hydrate thermal dissociation behavior and dissociation enthalpies in methane-carbon dioxide swapping process [J]. The Journal of Chemical Thermodynamics, 2018, 117: 33-42. doi: 10.1016/j.jct.2017.08.018

[23] Ota M, Abe Y, Watanabe M, et al. Methane recovery from methane hydrate using pressurized CO2 [J]. Fluid Phase Equilibria, 2005, 228-229: 553-559. doi: 10.1016/j.fluid.2004.10.002

[24] Yezdimer E M, Cummings P T, Chialvo A A. Determination of the Gibbs free energy of gas replacement in SI clathrate hydrates by molecular simulation [J]. The Journal of Physical Chemistry A, 2002, 106(34): 7982-7987. doi: 10.1021/jp020795r

[25] Huo Z X, Hester K, Sloan E D Jr, et al. Methane hydrate nonstoichiometry and phase diagram [J]. AIChE Journal, 2003, 49(5): 1300-1306. doi: 10.1002/aic.690490521

[26] Circone S, Stern L A, Kirby S H, et al. CO2 hydrate: synthesis, composition, structure, dissociation behavior, and a comparison to structure I CH4 hydrate [J]. The Journal of Physical Chemistry B, 2003, 107(23): 5529-5539. doi: 10.1021/jp027391j

[27] Geng C Y, Wen H, Zhou H. Molecular simulation of the potential of methane reoccupation during the replacement of methane hydrate by CO2 [J]. The Journal of Physical Chemistry A, 2009, 113(18): 5463-5469. doi: 10.1021/jp811474m

[28] Yonkofski C M R, Horner J A, White M D. Experimental and numerical investigation of hydrate-guest molecule exchange kinetics [J]. Journal of Natural Gas Science and Engineering, 2016, 35: 1480-1489. doi: 10.1016/j.jngse.2016.03.080

[29] 张杰, 关富佳. CO2置换联合热采技术开采天然气水合物可行性分析[J]. 能源化工, 2018, 39(2):71-75 doi: 10.3969/j.issn.1006-7906.2018.02.015 ZHANG Jie, GUAN Fujia. Feasibility analysis on CO2 replacement combined with heating technology for production of natural gas hydrate [J]. Energy Chemical Industry, 2018, 39(2): 71-75. doi: 10.3969/j.issn.1006-7906.2018.02.015

[30] 颜雨. CO2乳液稳定性评价和CO2乳液盖层改造降压开采水合物研究[D]. 中国石油大学(北京)硕士学位论文, 2019 YAN Yu. Experimental study on stability of CO2 emulsion and hydrate depressurization exploitation after cap reformation via CO2 emulsion[D]. Master Dissertation of China University of Petroleum (Beijing), 2019.

[31] Lee S, Lee Y, Lee J, et al. Experimental verification of methane–carbon dioxide replacement in natural gas hydrates using a differential scanning calorimeter [J]. Environmental Science & Technology, 2013, 47(22): 13184-13190.

[32] Jung J W, Espinoza D N, Santamarina J C. Properties and phenomena relevant to CH4-CO2 replacement in hydrate-bearing sedim-ents [J]. Journal of Geophysical Research:Solid Earth, 2010, 115(B10): B10102. doi: 10.1029/2009JB000812

[33] Yuan Q, Sun C Y, Liu B, et al. Methane recovery from natural gas hydrate in porous sediment using pressurized liquid CO2 [J]. Energy Conversion and Management, 2013, 67: 257-264. doi: 10.1016/j.enconman.2012.11.018

[34] Yuan Q, Sun C Y, Yang X, et al. Recovery of methane from hydrate reservoir with gaseous carbon dioxide using a three-dimensional middle-size reactor [J]. Energy, 2012, 40(1): 47-58. doi: 10.1016/j.energy.2012.02.043

[35] Schicks J M, Strauch B, Heeschen K U, et al. From microscale (400 μl) to macroscale (425 L): Experimental investigations of the CO2/N2-CH4 exchange in gas hydrates simulating the Iġnik Sikumi Field Trial [J]. Journal of Geophysical Research:Solid Earth, 2018, 123(5): 3608-3620. doi: 10.1029/2017JB015315

[36] Gambelli A M, Filipponi M, Rossi F. How methane release may affect carbon dioxide storage during replacement processes in natural gas hydrate reservoirs [J]. Journal of Petroleum Science and Engineering, 2021, 205: 108895. doi: 10.1016/j.petrol.2021.108895

[37] Xu C G, Zhang W, Yan K F, et al. Research on micro mechanism and influence of hydrate-based methane-carbon dioxide replacement for realizing simultaneous clean energy exploitation and carbon emission reduction [J]. Chemical Engineering Science, 2022, 248: 117266. doi: 10.1016/j.ces.2021.117266

[38] Uchida T, Takeya S, Ebinuma T, et al. Replacing methane with CO2 in clathrate hydrate: observations using Raman spectroscopy[J]. 2001.

[39] Ors O, Sinayuc C. An experimental study on the CO2-CH4 swap process between gaseous CO2 and CH4 hydrate in porous media [J]. Journal of Petroleum Science and Engineering, 2014, 119: 156-162. doi: 10.1016/j.petrol.2014.05.003

[40] Mok J, Choi W, Seo Y. Time-dependent observation of a cage-specific guest exchange in sI hydrates for CH4 recovery and CO2 sequestration [J]. Chemical Engineering Journal, 2020, 389: 124434. doi: 10.1016/j.cej.2020.124434

[41] Xu C G, Cai J, Yu Y S, et al. Research on micro-mechanism and efficiency of CH4 exploitation via CH4-CO2 replacement from natural gas hydrates [J]. Fuel, 2018, 216: 255-265. doi: 10.1016/j.fuel.2017.12.022

[42] Zhang Y, Xiong L J, Li X S, et al. Replacement of CH4 in hydrate in porous sediments with liquid CO2 injection [J]. Chemical Engineering & Technology, 2014, 37(12): 2022-2029.

[43] 宋光春, 李玉星, 王武昌. 温度和压力对CO2置换甲烷水合物的影响[J]. 油气储运, 2016, 35(3):295-301 SONG Guangchun, LI Yuxing, WANG Wuchang. Impacts of temperature and pressure on displacement of CH4 in hydrate by CO2 [J]. Oil and Gas Storage and Transportation, 2016, 35(3): 295-301.

[44] Uchida T, Ikeda I Y, Takeya S, et al. Kinetics and stability of CH4-CO2 mixed gas hydrates during formation and long-term storage [J]. ChemPhysChem, 2005, 6(4): 646-654. doi: 10.1002/cphc.200400364

[45] Huang X, Cai W J, Zhan L S, et al. Study on the reaction of methane hydrate with gaseous CO2 by Raman imaging microscopy [J]. Chemical Engineering Science, 2020, 222: 115720. doi: 10.1016/j.ces.2020.115720

[46] Yoon J H, Kawamura T, Yamamoto Y, et al. Transformation of methane hydrate to carbon dioxide hydrate: In situ Raman spectroscopic observations[C]//The Fifteenth International Offshore and Polar Engineering Conference. Seoul, Korea: The International Society of Offshore and Polar Engineers, 2005.

[47] 王菲菲. 二氧化碳置换甲烷水合物微观实验研究[D]. 中国地质大学博士学位论文, 2015. WANG Feifei. Micro-experimental study onreplacement of CH4 hydrate by use of Co[D]. Doctor Dissertation of China University of Geosciences, 2015.

[48] Wang T, Zhang L X, Sun L J, et al. Methane recovery and carbon dioxide storage from gas hydrates in fine marine sediments by using CH4/CO2 replacement [J]. Chemical Engineering Journal, 2021, 425: 131562. doi: 10.1016/j.cej.2021.131562

[49] Pan D B, Zhong X P, Zhu Y, et al. CH4 recovery and CO2 sequestration from hydrate-bearing clayey sediments via CO2/N2 injection [J]. Journal of Natural Gas Science and Engineering, 2020, 83: 103503. doi: 10.1016/j.jngse.2020.103503

[50] Ren J J, Liu X H, Niu M Y, et al. Effect of sodium montmorillonite clay on the kinetics of CH4 hydrate-implication for energy recovery [J]. Chemical Engineering Journal, 2022, 437: 135368. doi: 10.1016/j.cej.2022.135368

[51] Gambelli A M. An experimental description of the double positive effect of CO2 injection in methane hydrate deposits in terms of climate change mitigation [J]. Chemical Engineering Science, 2021, 233: 116430. doi: 10.1016/j.ces.2020.116430

[52] Zhang X M, Wang Y M, Li J P, et al. Recovering CH4 from natural gas hydrate with CO2 in porous media below the freezing point [J]. Petroleum Science and Technology, 2019, 37(7): 770-779. doi: 10.1080/10916466.2019.1566248

[53] Khasanov M K, Stolpovsky M V, Gimaltdinov I K. Mathematical model of injection of liquid carbon dioxide in a reservoir saturated with methane and its hydrate [J]. International Journal of Heat and Mass Transfer, 2019, 132: 529-538. doi: 10.1016/j.ijheatmasstransfer.2018.12.033

[54] Khasanov M K, Musakaev N G, Stolpovsky M V, et al. Mathematical Model of decomposition of methane hydrate during the injection of liquid carbon dioxide into a reservoir saturated with methane and its hydrate [J]. Mathematics, 2020, 8(9): 1482. doi: 10.3390/math8091482

[55] Shagapov V S, Khasanov M K, Musakaev N G, et al. Theoretical research of the gas hydrate deposits development using the injection of carbon dioxide [J]. International Journal of Heat and Mass Transfer, 2017, 107: 347-357. doi: 10.1016/j.ijheatmasstransfer.2016.11.034

[56] Lee B R, Koh C A, Sum A K. Quantitative measurement and mechanisms for CH4 production from hydrates with the injection of liquid CO2 [J]. Physical Chemistry Chemical Physics, 2014, 16(28): 14922-14927. doi: 10.1039/C4CP01780C

[57] Qi Y X, Ota M, Zhang H. Molecular dynamics simulation of replacement of CH4 in hydrate with CO2 [J]. Energy Conversion and Management, 2011, 52(7): 2682-2687. doi: 10.1016/j.enconman.2011.01.020

[58] Tung Y T, Chen L J, Chen Y P, et al. In situ methane recovery and carbon dioxide sequestration in methane hydrates: A molecular dynamics simulation study [J]. The Journal of Physical Chemistry B, 2011, 115(51): 15295-15302. doi: 10.1021/jp2088675

[59] Hsieh P Y, Sean W Y, Sato T, et al. Mesoscale modeling of exploiting methane hydrate by CO2 replacement in homogeneous porous media [J]. International Journal of Heat and Mass Transfer, 2020, 158: 119741. doi: 10.1016/j.ijheatmasstransfer.2020.119741

[60] Bai D S, Zhang X R, Chen G J, et al. Replacement mechanism of methane hydrate with carbon dioxide from microsecond molecular dynamics simulations [J]. Energy & Environmental Science, 2012, 5(5): 7033-7041.

[61] 刘一楠. 基于分子动力学模拟的天然气水合物分解和置换过程机理研究[D]. 天津大学硕士学位论文, 2017. LIU Yinan. Mechanism study on the decomposition andreplacement of natural gas hydrate basedon molecular dynamics simulation[D]. Master Dissertation of Tianjin University, 2017.

[62] Ota M, Morohashi K, Abe Y, et al. Replacement of CH4 in the hydrate by use of liquid CO2 [J]. Energy Conversion and Management, 2005, 46(11-12): 1680-1691. doi: 10.1016/j.enconman.2004.10.002

[63] Ota M, Saito T, Aida T, et al. Macro and microscopic CH4-CO2 replacement in CH4 hydrate under pressurized CO2 [J]. AIChE Journal, 2007, 53(10): 2715-2721. doi: 10.1002/aic.11294

[64] 张凤琦, 陈国兴, 郭开华, 等. 液态二氧化碳置换整形甲烷水合物过程特性[J]. 过程工程学报, 2018, 18(3):639-645 doi: 10.12034/j.issn.1009-606X.217304 ZHANG Fengqi, CHEN Guoxing, GUO Kaihua, et al. Process characteristics on replacement of bulk-methane hydrates with liquid cardon dioxide [J]. The Chinese Journal of Process Engineering, 2018, 18(3): 639-645. doi: 10.12034/j.issn.1009-606X.217304

[65] Zhou X T, Fan S S, Liang D Q, et al. Determination of appropriate condition on replacing methane from hydrate with carbon dioxide [J]. Energy Conversion and Management, 2008, 49(8): 2124-2129. doi: 10.1016/j.enconman.2008.02.006

[66] Wang X H, Li F G, Xu Y X, et al. Elastic properties of hydrate-bearing sandy sediment during CH4-CO2 replacement [J]. Energy Conversion and Management, 2015, 99: 274-281. doi: 10.1016/j.enconman.2015.04.032

[67] Falenty A, Qin J, Salamatin A N, et al. Fluid composition and kinetics of the in-situ replacement in CH4-CO2 hydrate system [J]. The Journal of Physical Chemistry C, 2016, 120(48): 27159-27172. doi: 10.1021/acs.jpcc.6b09460

[68] Kvamme B, Graue A, Buanes T, et al. Storage of CO2 in natural gas hydrate reservoirs and the effect of hydrate as an extra sealing in cold aquifers [J]. International Journal of Greenhouse Gas Control, 2007, 1(2): 236-246. doi: 10.1016/S1750-5836(06)00002-8

[69] Zhou X T, Fan S S, Liang D Q, et al. Replacement of methane from quartz sand-bearing hydrate with carbon dioxide-in-water emulsion [J]. Energy & Fuels, 2008, 22(3): 1759-1764.

[70] 周锡堂, 樊栓狮, 梁德青. CO2乳状液置换天然气水合物中CH4的动力学研究[J]. 天然气地球科学, 2013, 24(2):259-264 ZHOU Xitang, FAN Shuanshi, LIANG Deqing. Kinetic research on replacement of methane in gas hydrate with carbon dioxide emulsion [J]. Natural Gas Geoscience, 2013, 24(2): 259-264.

[71] Deusner C, Bigalke N, Kossel E, et al. Methane production from gas hydrate deposits through injection of supercritical CO2 [J]. Energies, 2012, 5(7): 2112-2140. doi: 10.3390/en5072112

[72] Bi Y, Yang T, Guo K H. Determination of the upper-quadruple-phase equilibrium region for carbon dioxide and methane mixed gas hydrates [J]. Journal of Petroleum Science and Engineering, 2013, 101: 62-67. doi: 10.1016/j.petrol.2012.11.019

[73] McGrail B P, Zhu T, Hunter R B, et al. A new method for enhanced production of gas hydrates with CO2 [J]. Gas Hydrates:Energy Resource Potential and Associated Geologic Hazards, 2004, 2004: 12-16.

[74] Lee Y, Kim Y, Lee J, et al. CH4 recovery and CO2 sequestration using flue gas in natural gas hydrates as revealed by a micro-differential scanning calorimeter [J]. Applied Energy, 2015, 150: 120-127. doi: 10.1016/j.apenergy.2015.04.012

[75] Mu L, von Solms N. Methane production and carbon capture by hydrate swapping [J]. Energy & Fuels, 2017, 31(4): 3338-3347.

[76] Prasad P S R, Kiran B S. Stability and exchange of guest molecules in gas hydrates under the influence of CH4, CO2, N2 and CO2+N2 gases at low-pressures [J]. Journal of Natural Gas Science and Engineering, 2020, 78: 103311. doi: 10.1016/j.jngse.2020.103311

[77] Lim D, Ro H, Seo Y, et al. Thermodynamic stability and guest distribution of CH4/N2/CO2 mixed hydrates for methane hydrate production using N2/CO2 injection [J]. The Journal of Chemical Thermodynamics, 2017, 106: 16-21. doi: 10.1016/j.jct.2016.11.012

[78] Bhawangirkar D R, Sangwai J S. Insights into cage occupancies during gas exchange in CH4+CO2 and CH4+N2+CO2 mixed hydrate systems relevant for methane gas recovery and carbon dioxide sequestration in hydrate reservoirs: a thermodynamic approach [J]. Industrial & Engineering Chemistry Research, 2019, 58(31): 14462-14475.

[79] Matsui H, Jia J H, Tsuji T, et al. Microsecond simulation study on the replacement of methane in methane hydrate by carbon dioxide, nitrogen, and carbon dioxide-nitrogen mixtures [J]. Fuel, 2020, 263: 116640. doi: 10.1016/j.fuel.2019.116640

[80] Song W L, Sun X L, Zhou G G, et al. Molecular dynamics simulation study of N2/CO2 displacement process of methane hydrate [J]. ChemistrySelect, 2020, 5(44): 13936-13950. doi: 10.1002/slct.202003845

[81] Sun Y H, Li S L, Zhang G B, et al. Hydrate phase equilibrium of CH4+N2+CO2 gas mixtures and cage occupancy behaviors [J]. Industrial & Engineering Chemistry Research, 2017, 56(28): 8133-8142.

[82] Li B, Xu T F, Zhang G B, et al. An experimental study on gas production from fracture-filled hydrate by CO2 and CO2/N2 replacement [J]. Energy Conversion and Management, 2018, 165: 738-747. doi: 10.1016/j.enconman.2018.03.095

[83] 王晓辉. 注气开采天然气水合物实验模拟与能效分析[D]. 中国石油大学(北京)博士学位论文, 2017 WANG Xiaohui. Experimental simulation and energy efficiency analysis of gas hydrates production by gas injection method[D]. Doctor Dissertation of China University of Petroleum (Beijing), 2017.

[84] Chaturvedi K R, Sinha A S K, Nair V C, et al. Enhanced carbon dioxide sequestration by direct injection of flue gas doped with hydrogen into hydrate reservoir: Possibility of natural gas production [J]. Energy, 2021, 227: 120521. doi: 10.1016/j.energy.2021.120521

[85] Sun Y H, Zhang G B, Li S L, et al. CO2/N2 injection into CH4+C3H8 hydrates for gas recovery and CO2 sequestration [J]. Chemical Engineering Journal, 2019, 375: 121973. doi: 10.1016/j.cej.2019.121973

[86] Yasue M, Masuda Y, Liang Y F. Estimation of methane recovery efficiency from methane hydrate by the N2-CO2 gas mixture injection method [J]. Energy & Fuels, 2020, 34(5): 5236-5250.

[87] Liu B, Pan H, Wang X H, et al. Evaluation of different CH4-CO2 replacement processes in hydrate-bearing sediments by measuring P-wave velocity [J]. Energies, 2013, 6(12): 6242-6254. doi: 10.3390/en6126242

[88] Pandey J S, Solms N V. Hydrate stability and methane recovery from gas hydrate through CH4-CO2 replacement in different mass transfer scenarios [J]. Energies, 2019, 12(12): 2309. doi: 10.3390/en12122309

[89] Yang J H, Okwananke A, Tohidi B, et al. Flue gas injection into gas hydrate reservoirs for methane recovery and carbon dioxide sequestration [J]. Energy Conversion and Management, 2017, 136: 431-438. doi: 10.1016/j.enconman.2017.01.043

[90] 王曦. CO2+N2混合气置换开采天然气水合物实验研究及过程模拟[D]. 华南理工大学硕士学位论文, 2017. WANG Xi. Experimental research and process simulation of natural gas hydrate replacement production by injecting CO2+N2 mixture gas[D]. Master Dissertation of South China University of Technology, 2017.

[91] Park Y, Kim D Y, Lee J W, et al. Sequestering carbon dioxide into complex structures of naturally occurring gas hydrates [J]. Proceedings of the National Academy of Sciences, 2006, 103(34): 12690-12694. doi: 10.1073/pnas.0602251103

[92] Koh D Y, Kang H, Kim D O, et al. Recovery of methane from gas hydrates intercalated within natural sediments using CO2 and a CO2/N2 gas mixture [J]. ChemSusChem, 2012, 5(8): 1443-1448. doi: 10.1002/cssc.201100644

[93] Cha M J, Shin K, Lee H, et al. Kinetics of methane hydrate replacement with carbon dioxide and nitrogen gas mixture using in situ NMR spectroscopy [J]. Environmental Science & Technology, 2015, 49(3): 1964-1971.

[94] Koh D Y, Ahn Y H, Kang H, et al. One-dimensional productivity assessment for on-field methane hydrate production using CO2/N2 mixture gas [J]. AIChE Journal, 2015, 61(3): 1004-1014. doi: 10.1002/aic.14687

[95] Youn Y, Cha M J, Kwon M, et al. One-dimensional approaches for methane hydrate production by CO2/N2 gas mixture in horizontal and vertical column reactor [J]. Korean Journal of Chemical Engineering, 2016, 33(5): 1712-1719. doi: 10.1007/s11814-015-0294-5

[96] Pan D B, Zhong X P, Li B, et al. Experimental investigation into methane production from hydrate-bearing clayey sediment by CO2/N2 replacement [J]. Energy Exploration & Exploitation, 2020, 38(6): 2601-2617.

[97] 潘栋彬. 海洋天然气水合物射流破碎与注CO2/N2置换联合开采研究[D]. 吉林大学, 2021. PAN Dongbin. Research on joint exploitation of marine gas hydrate jet fragmentation and CO2/N2 replacement [D]. Jilin University, 2021.

[98] Niu M Y, Wu G Z, Yin Z Y, et al. Effectiveness of CO2-N2 injection for synergistic CH4 recovery and CO2 sequestration at marine gas hydrates condition [J]. Chemical Engineering Journal, 2021, 420: 129615. doi: 10.1016/j.cej.2021.129615

[99] Seo Y, Kang S P, Jang W. Study on mechanism of methane hydrate replacement by carbon dioxide injection[C]//The Nineteenth International Offshore and Polar Engineering Conference. Osaka, Japan: The International Society of Offshore and Polar Engineers, 2009.

[100] Zhou X B, Liang D Q, Liang S, et al. Recovering CH4 from natural gas hydrates with the injection of CO2-N2 gas mixtures [J]. Energy & Fuels, 2015, 29(2): 1099-1106.

[101] Ouyang Q, Fan S S, Wang Y H, et al. Enhanced methane production efficiency with in situ intermittent heating assisted CO2 replacement of hydrates [J]. Energy & Fuels, 2020, 34(10): 12476-12485.

[102] 操原. 二氧化碳与氮气混合气辅热联合置换开采天然气水合物实验研究[D]. 华南理工大学硕士学位论文, 2018. CAO Yuan. Experimental study on gas hydrate exploitation by combining N2 and CO2 mixture replacement and heat injection[D]. Master Dissertation of South China University of Technology, 2018.

[103] Masuda Y. Methane recovery from hydrate-bearing sediments by N2-CO2 gas mixture injection: experimental investigation on CO2-CH4 exchange ratio[C]//International Conference on Gas Hydrate. 2011.

[104] Tupsakhare S S, Castaldi M J. Efficiency enhancements in methane recovery from natural gas hydrates using injection of CO2/N2 gas mixture simulating in-situ combustion [J]. Applied Energy, 2019, 236: 825-836. doi: 10.1016/j.apenergy.2018.12.023

[105] 余静薇, 祁影霞, 魏欣宇. Ar提高CO2置换CH4水合物置换率研究[J]. 热能动力工程, 2020, 35(6):251-256 YU Jingwei, QI Yingxia, WEI Xinyu. Promotion of replacement rate of CH4 hydrates with CO2 by adding small Ar gas [J]. Journal of Engineering for Thermal Energy and Power, 2020, 35(6): 251-256.

[106] Okwananke A, Yang J H, Tohidi B, et al. Enhanced depressurisation for methane recovery from gas hydrate reservoirs by injection of compressed air and nitrogen [J]. The Journal of Chemical Thermodynamics, 2018, 117: 138-146. doi: 10.1016/j.jct.2017.09.028

[107] 穆德富, 祁影霞. 热激励的CO2置换CH4水合物的实验研究[J]. 能源研究与信息, 2017, 33(1):13-18 MU Defu, QI Yingxia. Experimental study on the replacement of methane hydrate by CO2 with thermal excitation [J]. Energy Research and Information, 2017, 33(1): 13-18.

[108] Zhang L X, Yang L, Wang J Q, et al. Enhanced CH4 recovery and CO2 storage via thermal stimulation in the CH4/CO2 replacement of methane hydrate [J]. Chemical Engineering Journal, 2017, 308: 40-49. doi: 10.1016/j.cej.2016.09.047

[109] Stanwix P L, Rathnayake N M, De Obanos F P P, et al. Characterising thermally controlled CH4-CO2 hydrate exchange in unconsolidated sediments [J]. Energy & Environmental Science, 2018, 11(7): 1828-1840.

[110] 欧阳潜. 置换联合原位加热强化开采天然气水合物及逆置换研究[D]. 华南理工大学硕士学位论文, 2020. OUYANG Qian. Investigation of replacement combined with in-situ heating enhanced exploitation of natural gas hydrates and the inverse[D]. Master Dissertation of South China University of Technology, 2020.

[111] 张育诚. 注热及CO2/N2置换开采天然气水合物实验研究[D]. 华南理工大学硕士学位论文, 2019 ZHANG Yucheng. Recovery CHA via thermal stimulation and CO2/N2 nreplacement of methane hydrate[D]. Master Dissertation of South China University of Technology, 2019.

[112] Tupsakhare S S, Fitzgerald G C, Castaldi M J. Thermally assisted dissociation of methane hydrates and the impact of CO2 injection [J]. Industrial & Engineering Chemistry Research, 2016, 55(39): 10465-10476.

[113] Zhao J F, Chen X Q, Song Y C, et al. Experimental study on a novel way of methane hydrates recovery: combining CO2 replacement and depressurization [J]. Energy Procedia, 2014, 61: 75-79. doi: 10.1016/j.egypro.2014.11.910

[114] Zhao J F, Zhang L X, Chen X Q, et al. Combined replacement and depressurization methane hydrate recovery method [J]. Energy Exploration & Exploitation, 2016, 34(1): 129-139.

[115] Ouyang Q, Pandey J S, Von Solms N. Critical parameters influencing mixed CH4/CO2 hydrates dissociation during multistep depressurization[J]. Fuel, 2022, 320: 123985.

[116] Lee Y, Deusner C, Kossel E, et al. Influence of CH4 hydrate exploitation using depressurization and replacement methods on mechanical strength of hydrate-bearing sediment [J]. Applied Energy, 2020, 277: 115569. doi: 10.1016/j.apenergy.2020.115569

[117] Mohammadi A H, Eslamimanesh A, Richon D. Semi-clathrate hydrate phase equilibrium measurements for the CO2+H2/CH4+tetra-n-butylammonium bromide aqueous solution system [J]. Chemical Engineering Science, 2013, 94: 284-290. doi: 10.1016/j.ces.2013.01.063

[118] 龙小军. TBAB和TEAB存在下水合物法生物气脱碳技术研究[D]. 华南理工大学硕士学位论文, 2017. LONG Xiaojun. Study on hydrate based biogas decarburization technology in the presence of TBAB and TEAB[D]. Master Dissertation of South China University of Technology, 2017.

[119] Babu P, Chin W I, Kumar R, et al. Systematic evaluation of tetra-n-butyl ammonium bromide (TBAB) for carbon dioxide capture employing the clathrate process [J]. Industrial & Engineering Chemistry Research, 2014, 53(12): 4878-4887.

[120] 王乐, 祁影霞, 邢艳青, 等. 置换法开采天然气水合物的实验研究[J]. 现代化工, 2014, 34(4):89-92 doi: 10.16606/j.cnki.issn0253-4320.2014.04.043 WANG Le, QI Yingxia, XING Yanqing, et al. Experimental study on exploitation of natural gas hydrate by replacement with CO2 [J]. Modern Chemical Industry, 2014, 34(4): 89-92. doi: 10.16606/j.cnki.issn0253-4320.2014.04.043

[121] Ricaurte M, Dicharry C, Renaud X, et al. Combination of surfactants and organic compounds for boosting CO2 separation from natural gas by clathrate hydrate formation [J]. Fuel, 2014, 122: 206-217. doi: 10.1016/j.fuel.2014.01.025

[122] Gambelli A M, Castellani B, Nicolini A, et al. Water salinity as potential aid for improving the carbon dioxide replacement process’ effectiveness in natural gas hydrate reservoirs [J]. Processes, 2020, 8(10): 1298. doi: 10.3390/pr8101298

[123] Gambelli A M, Castellani B, Filipponi M, et al. Chemical inhibitors as potential allied for CO2 replacement in gas hydrates reservoirs: Sodium chloride case study[C]//Proceedings of the 6th World Congress on Mechanical, Chemical, and Material Engineering (MCM'20). Prague, Czech Republic: ICCPE, 2020, 18.

[124] Liu X J, Ren J J, Chen D Y, et al. Comparison of SDS and L-Methionine in promoting CO2 hydrate kinetics: Implication for hydrate-based CO2 storage [J]. Chemical Engineering Journal, 2022, 438: 135504. doi: 10.1016/j.cej.2022.135504

-

期刊类型引用(2)

1. 王婷,邹春辉,毛龙江,周玉龙,莫多闻. 渤海湾西岸CZ01钻孔沉积物粒度端元分析及其气候—海平面变化响应. 古地理学报. 2022(06): 1224-1237 .  百度学术

百度学术

2. 王兆夺,于东生,汪卫国,罗福生,杨金艳. 泉州湾表层沉积物粒度分形特征与沉积学关系研究. 海洋湖沼通报. 2021(05): 82-88 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: