PRESSURE PULSE-DECAY METHOD AND ITS APPLICATION TO PERMEABILITY MEASUREMENT OF HYDRATE-BEARING SEDIMENTS

-

摘要: 含水合物沉积物渗透率是水合物开采相关工作的基础参数之一。稳态法在应用于渗透率较低的多孔介质时存在着稳定渗流难和试验耗时长等缺点。目前,含水合物细颗粒沉积物渗透率试验数据积累明显不足。本文首先介绍了瞬态压力脉冲法的基本原理及数据处理方法,然后以模拟试验验证了瞬态压力脉冲法的适用性,最后探讨了该方法在松散含水合物沉积物渗透率测量方面的应用效果。结果表明:瞬态压力脉冲法近似解处理粉细砂沉积物试验数据效果较好,而处理黏土沉积物试验数据存在明显误差,建议采用数值模拟反演分析的方法处理瞬态压力脉冲法试验数据;瞬态压力脉冲法适用于松散沉积物渗透率测量,在含水合物沉积物渗透率试验研究方面具有潜在的应用前景。Abstract: The permeability of hydrate-bearing sediments is one of the basic parameters to natural gas hydrate exploitation. Steady methods for measuring the permeability are time-consuming and require a steady seepage which is usually difficult to achieve. It is clear that there is a lack of experimental permeability data for fine-grained sediments that contain gas hydrate. To meet the needs of the kind, the pressure pulse decay method and its data processing are firstly introduced in this paper. Then we discussed the application of the method to hydrate-bearing sediments based on calculated data. It is concluded that the approximate solution to experimental data gives good results to coarse-grained sediments, but has some deviations when it is used for fine-grained sediments. In this regard, parametric inversion is suggested. To sum up, the transient pressure pulse decay method is feasible to permeability measurements of unconsolidated sediments, and has a vast potential for future development.

-

天然气水合物(简称水合物)是一种由天然气和水在一定的压力和温度条件下形成的似冰雪笼型化合物,被认为是潜在的替代能源之一[1]。水合物广泛分布于高纬度极地冻土地层以及海洋湖泊等深水地层中,具有能量密度高和储量巨大等特点[2]。近年来,水合物试采已经在加拿大马更些三角洲冻土区[3]、美国阿拉斯加北部冻土区[4]、日本南海海槽[5]和中国南海北部海域[6]等进行了数次,但现有的水合物开采技术仍然无法满足商业化开采的需求。渗透率是水合物开采多相渗流过程的重要参数,是水合物开采储层评价、产能预测和实施方案设计优化等工作的基础参数之一,对其开展研究具有重要的现实意义[7-10]。

国内外专家学者采用稳态法对含水合物中粗砂样品渗透率进行了测量,积累了丰富的试验数据并取得了一定的研究成果[11-15],但是该方法在应用于含水合物细颗粒沉积物渗透率测量时存在着稳态渗流难[16]和试验耗时长[17]等缺点。目前,含水合物粉砂、粉土和黏土样品渗透率试验数据积累明显不足。瞬态压力脉冲法基于被测样品两端压差随时间衰减测量数据确定渗透率,具有试验耗时短和测量精度高等优点[18],测量时不需要达到稳定渗流状态,特别适用于页岩和泥岩等渗透性较差的样品渗透率测量[19-21],在岩土工程和油气藏工程等多个领域取得了良好的应用效果[22-26]。然而,采用瞬态压力脉冲法测量松散沉积物渗透率的试验研究尚未见报道。

本文首先介绍瞬态压力脉冲法的基本原理与控制方程及其求解方法,随后以试验数据验证瞬态压力脉冲法对松散沉积物的适用性,最后探讨瞬态压力脉冲法在含水合物沉积物渗透率测量方面的应用效果。

1. 瞬态压力脉冲法

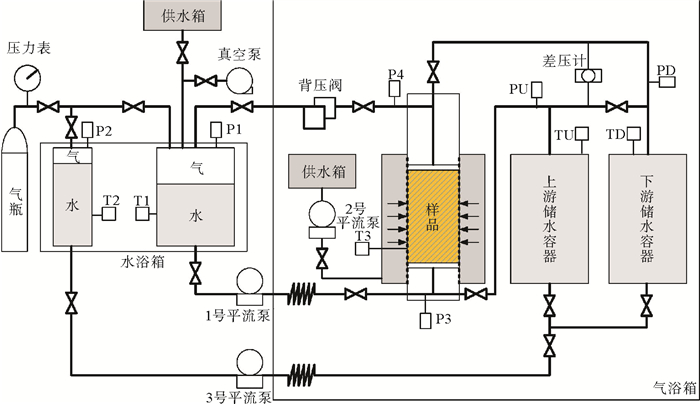

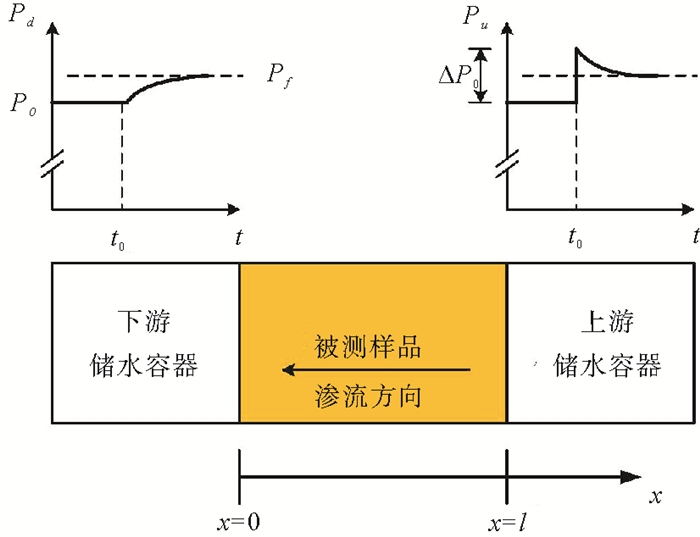

瞬态压力脉冲法测量过程如图 1所示。初始条件下,样品孔隙压力和两端储水容器压力处于平衡状态;向右端储水容器施加一个压力脉冲后,样品内出现由右向左的非定常渗流过程,该过程直到两端储水容器压力再次平衡后停止。与稳态法相比,瞬态压力脉冲法不需要被测样品内的渗流达到定常状态即可完成测量,根据样品两端压差衰减数据即可确定样品渗透率的大小。

上述非定常渗流过程的控制方程[19]如下所示:

$$ \frac{{{S}_{s}}}{K}\frac{\partial h}{\partial t}-\frac{{{\partial }^{2}}h}{\partial {{x}^{2}}}=0, 0<x<l\ t>{{t}_{0}} $$ $$ h\left( x, {{t}_{0}} \right)={{h}_{0}}, 0\le x\le l $$ $$ \mathit{h}\text{(}\mathit{0, t}\text{)=}{{\mathit{h}}_{\mathit{d}}}\text{(}\mathit{t}\text{), }\mathit{ t>}{{\mathit{t}}_{\mathit{0}}} $$ $$ \mathit{h}\text{(}\mathit{l}\text{, }\mathit{t}\text{)=}{{\mathit{h}}_{\mathit{u}}}\text{(}\mathit{t}\text{), }\mathit{t>}{{\mathit{t}}_{\text{0}}} $$ $$ \frac{{{S}_{d}}}{KA}\frac{\text{d}{{h}_{d}}}{\text{d}t}-{{\left( \frac{\partial h}{\partial x} \right)}_{x=0}}=0, t>{{t}_{0}} $$ $$ {{h}_{d}}\left( {{t}_{0}} \right)={{h}_{0}} $$ $$ \frac{{{S}_{u}}}{KA}\frac{\text{d}{{h}_{u}}}{\text{d}t}-{{\left( \frac{\partial h}{\partial x} \right)}_{x=l}}=0, t>{{t}_{0}} $$ $$ {{h}_{u}}\left( {{t}_{0}} \right)={{h}_{0}}+\Delta {{h}_{0}} $$ $$ {{h}_{0}}=\frac{{{P}_{0}}}{{{\rho }_{w}}g}, \Delta {{h}_{0}}=\frac{\Delta {{P}_{0}}}{{{\rho }_{w}}g}, K=\frac{k{{\gamma }_{w}}}{{{\mu }_{w}}} $$ $$ {{S}_{s}}={{\gamma }_{w}}\left[ n{{C}_{w}}+{{C}_{eff}}-(1+n){{C}_{m}} \right] $$ $$ {{S}_{d}}={{\gamma }_{w}}{{C}_{w}}{{V}_{d}}, {{S}_{u}}={{\gamma }_{w}}{{C}_{w}}{{V}_{u}} $$ 式中,h表示水头;P表示压力;ρ表示密度;g表示重力加速度;A表示样品横截面的面积;K表示样品渗透系数;k表示样品渗透率;μ表示动力粘滞系数;γ表示比重;下标s表示样品,下标w表示水,下表m表示样品骨架颗粒,下标u表示上游储水容器,即右端储水容器,下标d表示下游储水容器,即左端储水容器;S表示压缩存储系数,定义为单位压强变化引起的储水量变化;C表示有效压缩系数;V表示储水容器体积;n表示孔隙度;Ceff表示样品的有效压缩系数。

对于花岗岩等固结岩心,其压缩储存系数Ss非常小通常可以被忽略[27],在两端储水容器容积远远大于样品孔隙体积的条件下,上述控制方程存在以下近似解[19]:

$$ \ln \left( \frac{\Delta h}{\Delta {{h}_{0}}} \right)=-\frac{kA}{{{\mu }_{w}}{{C}_{w}}l}\left( \frac{1}{{{V}_{u}}}+\frac{1}{{{V}_{d}}} \right)t $$ 基于上式分析获得的样品两端无量纲压差随时间衰减试验数据即可确定样品渗透率的大小。

对于未固结的松散沉积物,其孔隙度通常是固结岩心孔隙度的数倍,其有效压缩系数通常大于固结岩心有效压缩系数,故样品压缩存储系数Ss通常不可以忽略。对于松散沉积物,建议采用数值模拟反演分析的方法确定样品的渗透率,即通过试验测量确定除样品渗透率以外的所有模型参数,不断调整渗透率的大小模拟试验获得的样品两端压差随时间衰减的过程,模拟效果最优对应的渗透率值即为被测样品的渗透率值。

2. 方法验证与应用分析

2.1 试验装置

采用瞬态压力脉冲法测量渗透率的试验装置如图 2所示。该试验装置主要由反应釜、围压加载模块、温度控制模块、流体供给模块和数据测量模块组成。反应釜内的被测样品尺寸为直径60 mm、高度100 mm;上游储水容器和下游储水容器的容积均为2 000 ml;围压加载模块的施加上限为20 MPa,精度为±0.1 MPa;恒温水浴槽(上海田枫实业有限公司)温度控制范围是5~35 ℃,精度为±1 ℃;恒温气浴箱(杭州雪中炭恒温技术有限公司)温度控制范围是-30~30 ℃,精度为±0.1 ℃;压力传感器(美国西特公司)的量程为40 MPa,精度为±0.25% FS;差压传感器(美国霍尼韦尔公司)的量程为1 MPa,精度为±0.065% FS。

2.2 试验材料与步骤

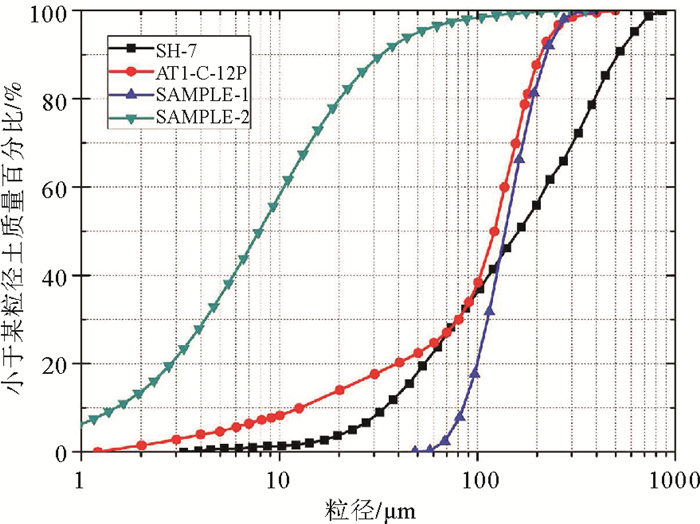

所用松散沉积物包括两种:中值粒径为120 μm的1号样品和中值粒径为8 μm的2号样品。上述两种样品的粒径级配曲线及其与现场样品粒径级配曲线的相对关系如图 3所示。可以看出,1号样品的中值粒径与现场样品的中值粒径相当,但是其细颗粒含量明显少于现场样品的细颗粒含量;2号样品的中值粒径小于现场样品的中值粒径,并且其黏土含量明显高于现场样品的黏土含量。

试验步骤如下:

(1) 安装沉积物样品并施加一定初始围压,从样品底部注水使其达到饱和状态;

(2) 逐渐增加围压至目标值,样品排水固结,记录此过程中样品的体积变形量;

(3) 打开阀门连通样品与两个储水容器,使其压力处于平衡状态;

(4) 关闭上游储水容器阀门,高压平流泵增压以施加压力脉冲(增量);

(5) 打开上游储水容器阀门,采用差压传感器记录上游储水容器和下游储水容器之间差压随时间变化的数据,待差压衰减至零时瞬态压力脉冲法测量过程结束;

(6) 关闭上游储水容器和下游储水容器的两个阀门,采用高压平流泵以固定流速循环注水,测量样品两端相对稳定的差压,基于恒流法再次确定样品渗透率的大小。

2.3 瞬态压力脉冲法适用性验证

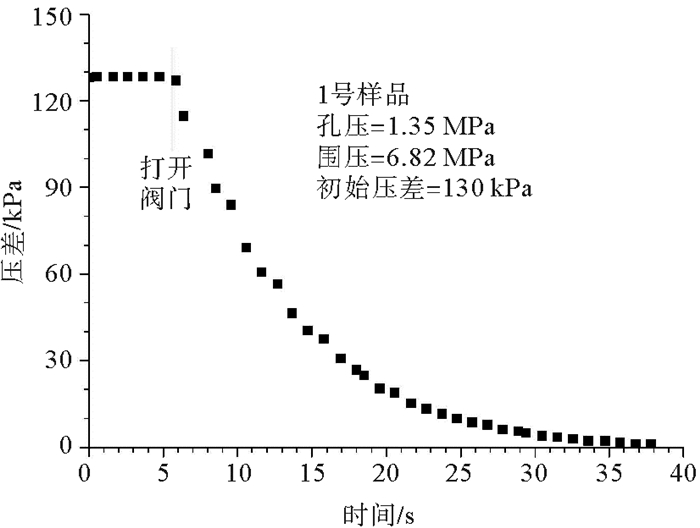

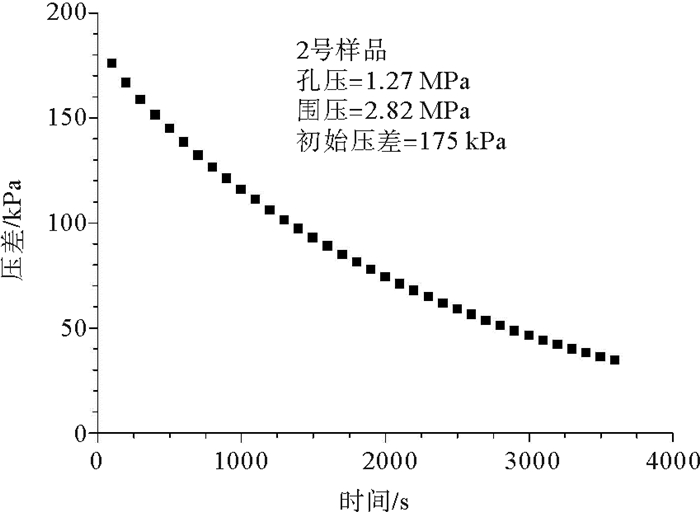

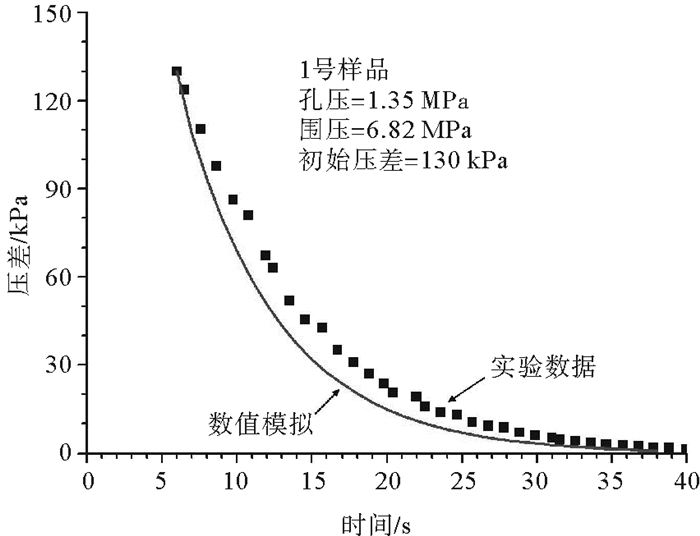

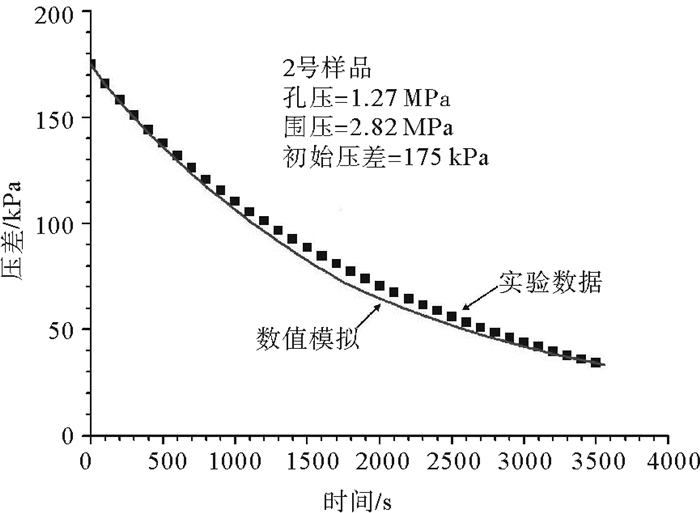

瞬态压力脉冲法测量过程中样品两端差压随时间衰减过程如图 4和图 5所示。可以看出,1号样品的有效围压是5.47 MPa,差压在约30 s的时间里由初始值130 kPa非线性衰减至零;2号样品的有效围压是1.55 MPa,差压在约3 500 s的时间里由初始值175 kPa非线性衰减至30 kPa。

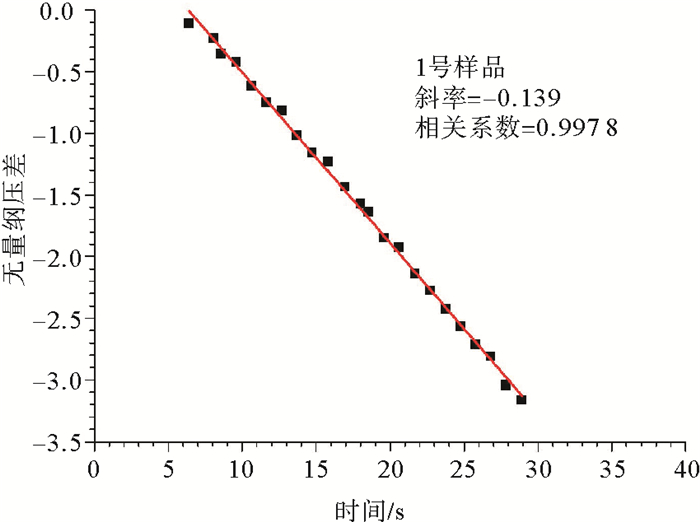

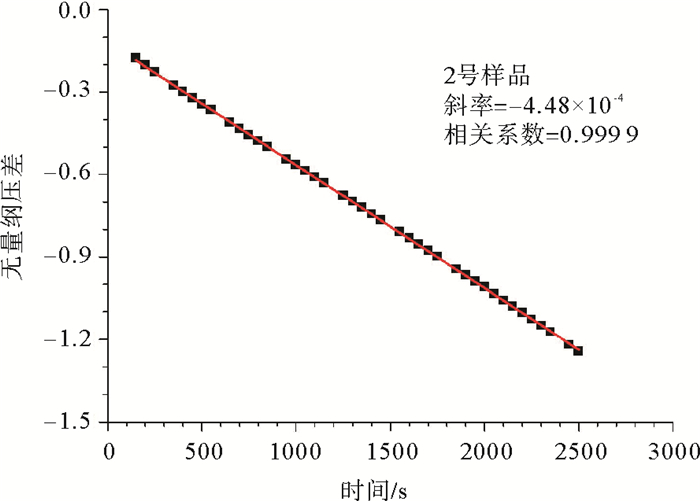

根据瞬态压力脉冲法非定常渗流过程控制方程的近似解,采用初始的样品两端差压对衰减差压进行无量纲化,取自然对数后其随时间变化情况如图 6和图 7所示。可以看出,两个样品的无量纲差压随时间衰减均呈现出良好的线性关系;1号样品拟合直线的斜率是-0.139,相关系数达到0.997 8;2号样品拟合直线的斜率是-4.48×10-4,相关系数达到0.999 9。按照下式可确定被测样品的渗透率:

$$ k=-m\frac{{{\mu }_{w}}{{C}_{w}}l}{A}{{\left( \frac{1}{{{V}_{w}}}+\frac{1}{{{V}_{d}}} \right)}^{-1}} $$ 采用有限差分法离散非定常渗流过程的控制方程后编制C语言求解程序,通过数值模拟反演分析确定样品的渗透率,模型参数如表 1所示。数值模拟获得的样品两端差压随时间衰减曲线如图 8和图 9所示。可以看出,数值模拟曲线与试验数据符合效果良好。

表 1 数值模拟所用参数Table 1. Parameters for numerical simulations参数名称 取值 水密度ρw(g/cm3) 1 水动力粘滞系数μw(Pas) 0.001 水压缩系数Cw(Pa-1) 4.2×10-10 上游水箱体积Vu(cm3) 2 000 下游水箱体积Vd(cm3) 2 000 被测样品长度l(cm) 10 被测样品横截面面积A(cm2) 28.3 矿物压缩系数Cm(Pa-1) 2×10-11 骨架压缩系数Ceff(Pa-1) 1号样品 0.35×10-8 2号样品 0.71×10-7 孔隙度n 1号样品 37.2% 2号样品 57.1% 备注:骨架压缩系数和孔隙度通过固结实验确定。 采用恒流法试验结果验证瞬态压力脉冲法测量松散沉积物渗透率的适用性,试验获得的样品渗透率结果如表 2所示。可以看出,对于1号样品,近似解法获得的渗透率大小与数值模拟反演分析获得的渗透率大小相当,并且瞬态压力脉冲法获得渗透率大小与恒流法获得的渗透率大小具有良好的一致性;对于2号样品,数值模拟反演分析获得的渗透率大小远远大于近似解法获得的渗透率大小,并且数值模拟反演分析获得渗透率大小与恒流法获得渗透率大小十分接近。

表 2 样品渗透试验结果Table 2. Experimental results of sample's permeability

瞬态压力脉冲法的近似解适用于粉细砂沉积物渗透率测量,而应用于黏土沉积物时存在着明显的误差。这主要是因为粉细砂沉积物在有效围压作用下固结速度相对较快,孔隙度有所减小且有效压缩系数变小,近似条件容易满足,故近似解确定的渗透率具有良好的准确性;然而,黏土沉积物孔隙度通常相对较高,有效压缩系数通常较大,即使在有效围压作用下发生固结,也无法满足近似条件,故近似解确定的渗透率存在明显的误差。因此,瞬态压力脉冲法的近似解适用于粉细砂沉积物,且有效围压越大,该方法的准确度越高;而对于黏土沉积物,建议采用数值模拟反演分析的方法处理试验数据以确定渗透率。

2.4 含水合物沉积物渗透性应用分析

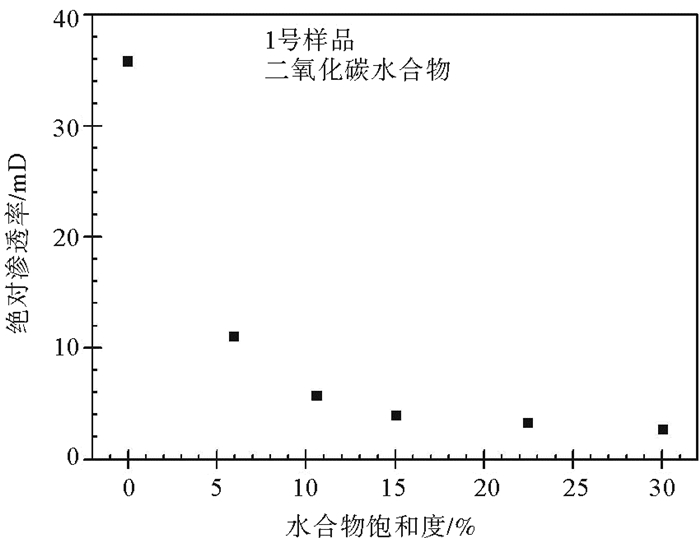

在1号样品中采用气过量法合成二氧化碳水合物[30],然后再用水驱气法制备饱和状态的含水合物沉积物[31]。采用瞬态压力脉冲法测量分解过程中不同水合物饱和度条件下含水合物沉积物渗透率,运用数值模拟反演分析确定渗透率大小,采用时域反射技术[32-34]测量水合物饱和度,试验结果如图 10所示。

由图 10可以看出,含水合物沉积物渗透率随着水合物饱和度的减小而非线性增加,这与前人的研究成果[12, 35, 36]具有良好的一致性,体现了瞬态压力脉冲法在含水合物沉积物渗透率测量方面具有良好的适用性。

3. 结论

本文介绍了瞬态压力脉冲法基本原理及数据处理方法,采用恒流法验证了瞬态压力脉冲法测量松散沉积物渗透率的适用性,分析了两种数据处理方法误差原因及其适用条件,探讨了瞬态压力脉冲法在含水合物沉积物渗透率测量方面的应用效果。主要结论如下:

(1) 瞬态压力脉冲法近似解处理粉细砂沉积物试验数据效果较好,而处理黏土沉积物试验数据存在明显误差;较高的有效围压有利于提升近似解的处理效果;建议采用数值模拟反演分析的方法处理瞬态压力脉冲法试验数据。

(2) 瞬态压力脉冲法适用于松散沉积物渗透率测量,在含水合物沉积物渗透率试验研究方面具有潜在的应用前景。

-

表 1 数值模拟所用参数

Table 1 Parameters for numerical simulations

参数名称 取值 水密度ρw(g/cm3) 1 水动力粘滞系数μw(Pas) 0.001 水压缩系数Cw(Pa-1) 4.2×10-10 上游水箱体积Vu(cm3) 2 000 下游水箱体积Vd(cm3) 2 000 被测样品长度l(cm) 10 被测样品横截面面积A(cm2) 28.3 矿物压缩系数Cm(Pa-1) 2×10-11 骨架压缩系数Ceff(Pa-1) 1号样品 0.35×10-8 2号样品 0.71×10-7 孔隙度n 1号样品 37.2% 2号样品 57.1% 备注:骨架压缩系数和孔隙度通过固结实验确定。 表 2 样品渗透试验结果

Table 2 Experimental results of sample's permeability

-

[1] Boswell R. Is gas hydrate energy within reach?[J]. Science, 2009, 325(5943): 957-958. doi: 10.1126/science.1175074

[2] Stern L A, Kirby S H, Durham W B. Peculiarities of methane clathrate hydrate formation and solid-state deformation, including possible superheating of water ice[J]. Science, 1996, 273(5283): 1843-1848. doi: 10.1126/science.273.5283.1843

[3] Numasawa M, Yamamoto K, Yasuda M, et al. Objectives and operation overview of the 2007 JOGMEC/NRCAN/AURORA Mallik 2L-38 gas hydrate production test[C]//Proceedings of the 6th International Conference on Gas Hydrates 2008. Vancouver, British Columbia, Canada, 2008.

[4] Schoderbek D, Farrell H, Howard J, et al. ConocoPhillips gas hydrate production test[R]. United States Department of Energy, 2013.

[5] Yamamoto K, Terao Y, Fujii T, et al. Operational overview of the first offshore production test of methane hydrates in the Eastern nankai Trough[C]//Offshore Technology Conference. Houston, Texas, USA: Offshore Technology Conference, 2014.

[6] 赵腊平, 张立.海域天然气水合物试采重大成果及最新进展发布[N].中国矿业报, 2017-06-05. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA2017S1095.htm ZHAO Laping, ZHANG Li. Achievement and progress announcements for marine gas hydrate production[N]. China Mining Daily, 2017-06-05. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA2017S1095.htm

[7] Liu L L, Lu X B, Zhang X H. A theoretical model for predicting the spatial distribution of gas hydrate dissociation under the combination of depressurization and heating without the discontinuous interface assumption[J]. Journal of Petroleum Science and Engineering, 2015, 133: 589-601. doi: 10.1016/j.petrol.2015.07.005

[8] Waite W F, Santamarina J C, Cortes D D, et al. Physical properties of hydrate-bearing sediments[J]. Reviews of Geophysics, 2009, 47(4): RG4003. http://d.old.wanfangdata.com.cn/OAPaper/oai_doaj-articles_5762815b05ef1bf0ed9be6fc1d599e2c

[9] Konno Y, Masuda Y, Hariguchi Y, et al. Key factors for depressurization-induced gas production from oceanic methane hydrates[J]. Energy and Fuels, 2010, 24(3): 1736-1744. doi: 10.1021/ef901115h

[10] Dai S, Seol Y. Water permeability in hydrate-bearing sediments: a pore-scale study[J]. Geophysical Research Letters, 2014, 41(12): 4176-4184. doi: 10.1002/2014GL060535

[11] Li B, Li X S, Li G, et al. Measurements of water permeability in unconsolidated porous media with methane hydrate formation[J]. Energies, 2013, 6(7): 3622-3636. doi: 10.3390/en6073622

[12] Delli M L, Grozic J L H. Experimental determination of permeability of porous media in the presence of gas hydrates[J]. Journal of Petroleum Science and Engineering, 2014, 120: 1-9. doi: 10.1016/j.petrol.2014.05.011

[13] Seol Y, Kneafsey T J. Methane hydrate induced permeability modification for multiphase flow in unsaturated porous media[J]. Journal of Geophysical Research: Solid Earth, 2011, 116(B8): B08102. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1029/2010JB008040

[14] Kneafsey T J, Seol Y, Gupta A, et al. Permeability of laboratory-formed methane-hydrate-bearing sand: measurements and observations using X-ray Computed Tomography[J]. SPE Journal, 2011, 16(1): 78-94. doi: 10.2118/139525-PA

[15] 宋永臣, 黄兴, 刘瑜, 等.含甲烷水合物多孔介质渗透性的实验研究[J].热科学与技术, 2010, 9(1): 51-57. http://d.old.wanfangdata.com.cn/Periodical/rkxyjs201001009 SONG Yongchen, HUANG Xing, LIU Yu, et al. Experimental study of permeability of porous medium containing methane hydrate[J]. Journal of Thermal Science and Technology, 2010, 9(1): 51-57. http://d.old.wanfangdata.com.cn/Periodical/rkxyjs201001009

[16] Johnson A, Patil S, Dandekar A. Experimental investigation of gas-water relative permeability for gas-hydrate-bearing sediments from the Mount Elbert Gas Hydrate Stratigraphic Test Well, Alaska North Slope[J]. Marine and Petroleum Geology, 2011, 28(2): 419-426. doi: 10.1016/j.marpetgeo.2009.10.013

[17] Marinakis D, Varotsis N, Perissoratis C. Gas hydrate dissociation affecting the permeability and consolidation behaviour of deep sea host sediment[J]. Journal of Natural Gas Science and Engineering, 2015, 23: 55-62. doi: 10.1016/j.jngse.2015.01.012

[18] Brace W F. Permeability of crystalline and argillaceous rocks[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1980, 17(5): 241-251. doi: 10.1016-0148-9062(80)90807-4/

[19] Hsieh P A, Tracy J V, Neuzil C E, et al. A transient laboratory method for determining the hydraulic properties of 'tight' rocks-I. Theory[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1981, 18(3): 245-252. http://www.sciencedirect.com/science/article/pii/0148906281909797

[20] Neuzil C E, Cooley C, Silliman S E, et al. A transient laboratory method for determining the hydraulic properties of 'tight' rocks-II. Application[J]. International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts, 1981, 18(3): 253-258. doi: 10.1016/0148-9062(81)90980-3

[21] Selvadurai A P S, Carnaffan P. A transient pressure pulse method for the mesurement of permeability of a cement grout[J]. Canadian Journal of Civil Engineering, 1997, 24(3): 489-502. doi: 10.1139/l96-132

[22] 李小春, 高桥学, 吴智深, 等.瞬态压力脉冲法及其在岩石三轴试验中的应用[J].岩石力学与工程学报, 2001, 20(S1): 1725-1733. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb2001z1025 LI Xiaochun, GAO Qiaoxue, WU Zhishen, et al. Transient pulse technique and its application to conventional triaxial compressive tests[J]. Chinese Journal of Rock Mechanics and Engineering, 2001, 20(S1): 1725-1733. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb2001z1025

[23] Billiotte J, Yang D, Su K. Experimental study on gas permeability of mudstones[J]. Physics and Chemistry of the Earth, Parts A/B/C, 2008, 33(S1): S231-S236. http://www.sciencedirect.com/science/article/pii/S1474706508002726

[24] Cui X, Bustin A M M, Bustin R M. Measurements of gas permeability and diffusivity of tight reservoir rocks: different approaches and their applications[J]. Geofluids, 2009, 9(3): 208-223. doi: 10.1111/j.1468-8123.2009.00244.x

[25] Ling K G, He J, Pei P, et al. Determining the permeability of tight rock with gas transient flow[J]. Journal of Natural Gas Science and Engineering, 2013, 15: 1-7. doi: 10.1016/j.jngse.2013.07.003

[26] Yang Z H, Sang Q, Dong M Z, et al. A modified pressure-pulse decay method for determining permeabilities of tight reservoir cores[J]. Journal of Natural Gas Science and Engineering, 2015, 27: 236-246. doi: 10.1016/j.jngse.2015.08.058

[27] Brace W F, Walsh J B, Frangos W T. Permeability of granite under high pressure[J]. Journal of Geophysical Research, 1968, 73(6): 2225-2236. doi: 10.1029/JB073i006p02225

[28] Liu C L, Ye Y G, Meng Q G, et al. The characteristics of gas hydrates recovered from shenhu area in the South China Sea[J]. Marine Geology, 2012, 307-310: 22-27. doi: 10.1016/j.margeo.2012.03.004

[29] Yoneda J, Masui A, Konno Y, et al. Mechanical properties of hydrate-bearing turbidite reservoir in the first gas production test site of the Eastern Nankai Trough[J]. Marine and Petroleum Geology, 2015, 66: 471-486. doi: 10.1016/j.marpetgeo.2015.02.029

[30] Ghiassian H, Grozic J L H. Strength behavior of methane hydrate bearing sand in undrained triaxial testing[J]. Marine and Petroleum Geology, 2013, 43: 310-319. doi: 10.1016/j.marpetgeo.2013.01.007

[31] Masui A, Haneda H, Ogata Y, et al. Effects of methane hydrate formation on shear strength of synthetic methane hydrate sediments[C]//The Fifteenth International Offshore and Polar Engineering Conference. Seoul, Korea: International Society of Offshore and Polar Engineers, 2005.

[32] 刘乐乐, 张旭辉, 刘昌岭, 等.含水合物沉积物三轴剪切试验与损伤统计分析[J].力学学报, 2016, 48(3): 720-729. http://d.old.wanfangdata.com.cn/Periodical/lxxb201603022 LIU Lele, ZHANG Xuhui, LIU Changling, et al. Triaxial shear tests and statistical analyses of damage for methane hydrate-bearing sediments[J]. Chinese Journal of Theoretical and Applied Mechanics, 2016, 48(3): 720-729. http://d.old.wanfangdata.com.cn/Periodical/lxxb201603022

[33] 孙建业, 业渝光, 刘昌岭, 等.沉积物中天然气水合物减压分解实验[J].现代地质, 2010, 24(3): 614-621. doi: 10.3969/j.issn.1000-8527.2010.03.028 SUN Jianye, YE Yuguang, LIU Changling, et al. Experimental research of gas hydrate dissociation in sediments by depressurization method[J]. Geoscience, 2010, 24(3): 614-621. doi: 10.3969/j.issn.1000-8527.2010.03.028

[34] 胡高伟, 业渝光, 刁少波, 等.时域反射技术测量海洋沉积物含水量的研究[J].现代地质, 2010, 24(3): 622-626. doi: 10.3969/j.issn.1000-8527.2010.03.029 HU Gaowei, YE Yuguang, DIAO Shaobo, et al. Research of time domain reflectometry in measuring water content of marine sediments[J]. Geoscience, 2010, 24(3): 622-626. doi: 10.3969/j.issn.1000-8527.2010.03.029

[35] Li C H, Zhao Q, Xu H J, et al. Relation between relative permeability and hydrate saturation in Shenhu area, South China Sea[J]. Applied Geophysics, 2014, 11(2): 207-214. doi: 10.1007/s11770-014-0432-6

[36] Kumar A, Maini B, Bishnoi P R, et al. Experimental determination of permeability in the presence of hydrates and its effect on the dissociation characteristics of gas hydrates in porous media[J]. Journal of Petroleum Science and Engineering, 2010, 70(1-2): 114-122. doi: 10.1016/j.petrol.2009.10.005

-

期刊类型引用(5)

1. 钟振,孟醒,胡云进,张丰收,李小双,周宇. 考虑基质渗透性的岩体单裂隙渗流及影响因素的室内和数值试验研究. 岩石力学与工程学报. 2023(09): 2148-2163 .  百度学术

百度学术

2. 王自豪,万义钊,刘乐乐,卜庆涛,王壮壮,毛佩筱,胡高伟. 含水合物沉积物相对渗透率研究进展. 海洋地质前沿. 2022(02): 14-29 .  百度学术

百度学术

3. 尹诗琪,王冬冬,张泽,柴华. 海洋细粒砂质水合物储层渗透率预测模型研究. 中国海上油气. 2022(03): 98-104 .  百度学术

百度学术

4. 刘乐乐,刘昌岭,吴能友,阮海龙,张永超,郝锡荦,卜庆涛. 天然气水合物储层岩心保压转移与测试进展. 地质通报. 2021(Z1): 408-422 .  百度学术

百度学术

5. 蔡建超,夏宇轩,徐赛,田海涛. 含水合物沉积物多相渗流特性研究进展. 力学学报. 2020(01): 208-223 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: